Automatic boiler blowdown systems

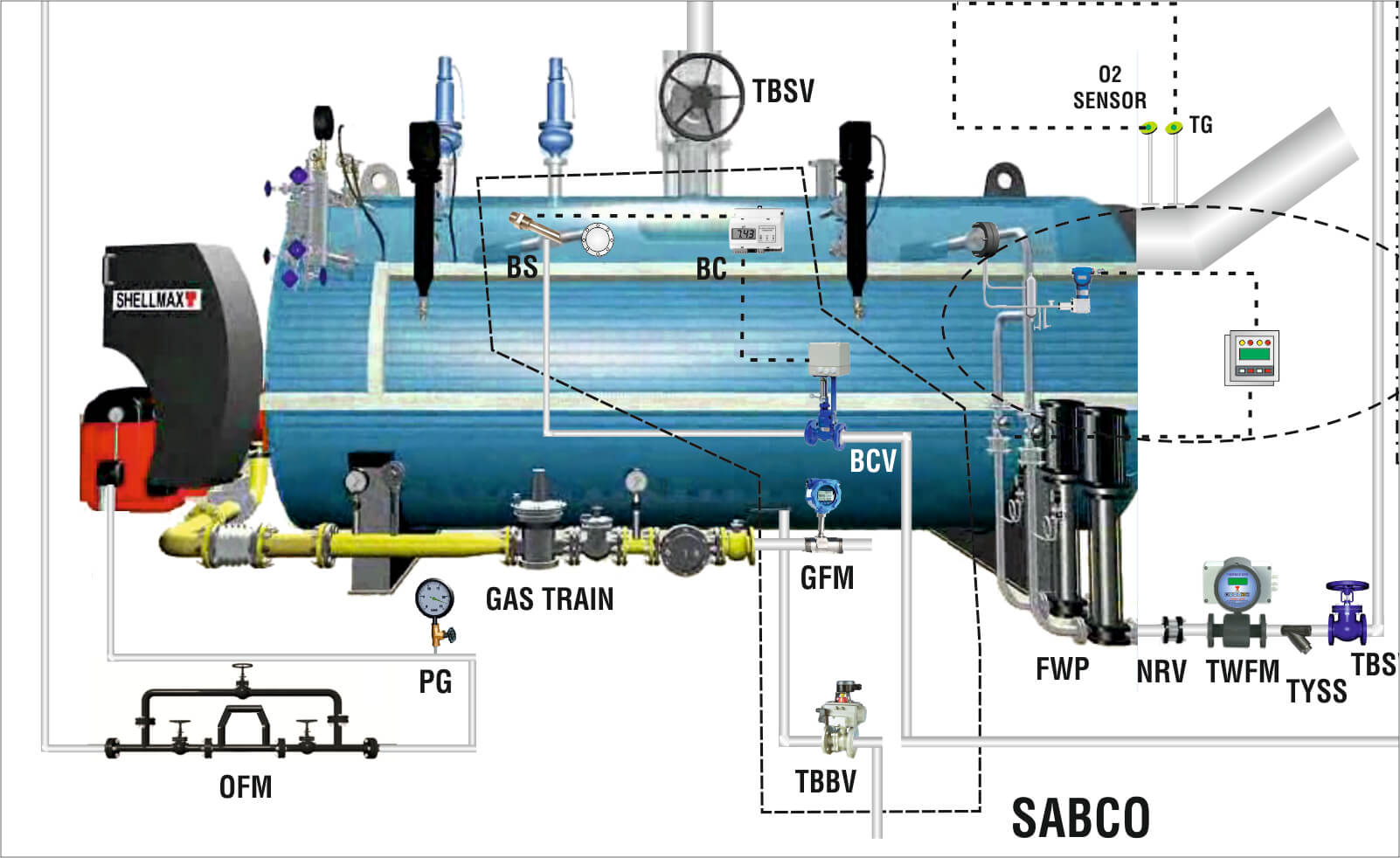

Automatic Boiler Blowdown Systems. Blowdown helps maintain boiler water level safety controls. Conductivity, or the total dissolved solids inside the boiler, is controlled only by the boiler surface blowdown valve. When sodium zeolite softened makeup is used, the need for boiler blowdown is usually. Volfram offers tdsbased auto blow down system which provides reliable, flexible and powerful control for your boiler.

Global B2B Marketplace To Advertise Your Business Online From keepital.com

Global B2B Marketplace To Advertise Your Business Online From keepital.com

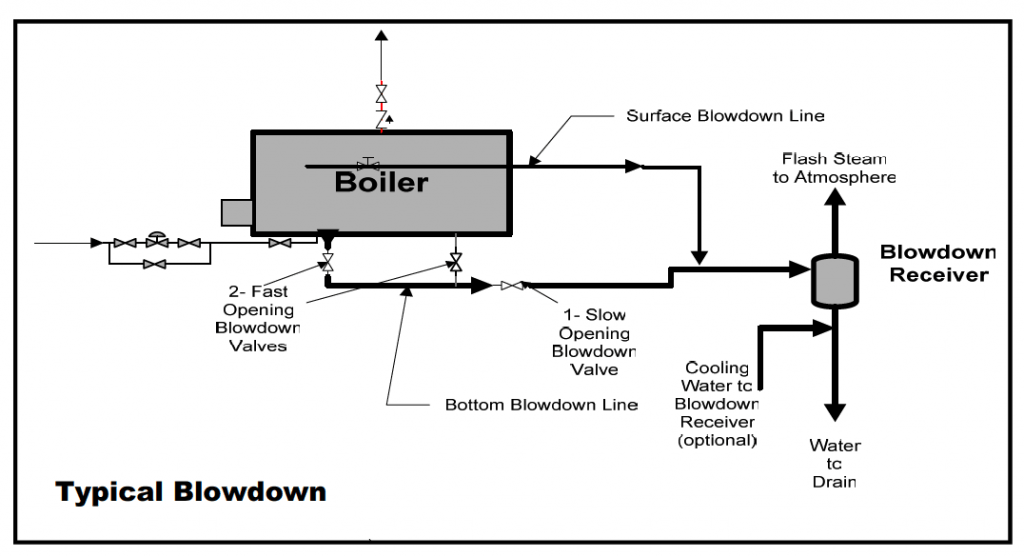

The system includes a blowdown tank connected to the bottom of a boiler. The sensor is connected to the controller that monitors and displays the tds inside boiler and takes the. Volfram offers reliable & complete solution for tds based automatic boiler blow down system. Boiler blowdown is the process of removing water from the system. The existing boiler blowdown system to recover the energy from the continuous blowdown stream from the boiler blowdown flash tank. The amount of blowdown required is directly related to the quality of the water being fed into the boiler.

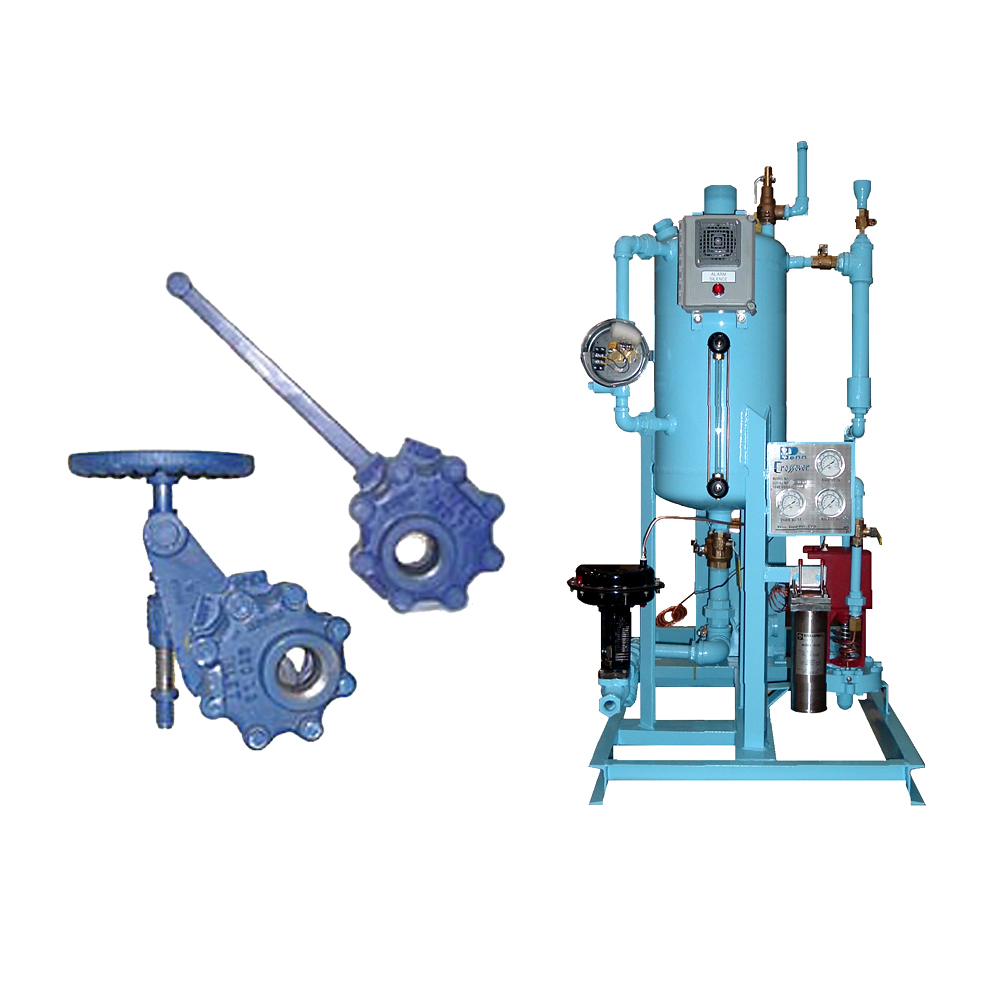

Key operated manual systems and fully automated systems are available.

The amount of blowdown necessary depends on boiler operating pressure, amount of makeup water, impurity levels in the makeup water, and the dissolved solids concentrations that a given boiler can tolerate. The system includes a blowdown tank connected to the bottom of a boiler. Boiler blowdown is the process of removing water from the system. Blowdown helps maintain boiler water level safety controls. So remember, the better the water quality, the less a. If an economical blowdown rate is to be maintained, suitable boiler water tests must be run frequently to check concentrations in the boiler water.

Source: bryanboilers.com

Source: bryanboilers.com

Spirax sarco us bottom blowdown systems provide efficient control of blowdown water, essential to maintaining steam quality & improve boiler efficiency. (energy efficiency tip of the day) tip summary • the primary and most efficient way to control boiler conductivity. When sodium zeolite softened makeup is used, the need for boiler blowdown is usually. Boiler automation and blowdown control is important. Scada demonstration for auto blowdown for boilers.#scada #plc #industrial_automation

Source: parkerboiler.com

Source: parkerboiler.com

Volfram offers reliable & complete solution for tds based automatic boiler blow down system. The automatic tds (total dissolved solids) systems monitor the build up of contamination in the boilers and initiate a boiler blowdown when the level of contaminants reaches a preset threshold. A blowdown system for controlling blowdown of a boiler such that the level of dissolved solids in the boiler is carefully controlled. If an economical blowdown rate is to be maintained, suitable boiler water tests must be run frequently to check concentrations in the boiler water. Blowoff tanks for specific applications and asme code requirements.

Source: hurstboiler.com

Source: hurstboiler.com

The amount of blowdown necessary depends on boiler operating pressure, amount of makeup water, impurity levels in the makeup water, and the dissolved solids concentrations that a given boiler can tolerate. Blowoff tanks for specific applications and asme code requirements. Epa and local standards generally require that boiler effluent be cooled below 140°f before discharge into a local sewer system. The blow down occurs too often, and does not allow the system to fully. The automatic boiler bottom blowdown systems market is appropriately divided into pivotal segments according to the report.

Source: ibhs.co.uk

Source: ibhs.co.uk

The controllers offer latest technology and. Spirax sarco us bottom blowdown systems provide efficient control of blowdown water, essential to maintaining steam quality & improve boiler efficiency. Automatic devices can never replace periodic manual inspection but offer peace of mind to those operating critical boiler systems. Improper control of the valve can lead to two issues: (energy efficiency tip of the day) tip summary • the primary and most efficient way to control boiler conductivity.

Source: keepital.com

Source: keepital.com

The sensor is connected to the controller that constantly monitors and displays the tds automatic boiler blow down system level & takes the control action whenever necessary. An automatic blowdown continuously monitors the quality of feed water as well as the quality of water inside a boiler shell and automatically opens as soon as the boiler water tds exceeds the permissible operating limit.this type of blowdown helps remove a maximum amount of dissolved solids with only minimal loss of water and heat from the boiler. If an economical blowdown rate is to be maintained, suitable boiler water tests must be run frequently to check concentrations in the boiler water. The existing boiler blowdown system to recover the energy from the continuous blowdown stream from the boiler blowdown flash tank. So remember, the better the water quality, the less a.

Source: ecdi.com

Source: ecdi.com

So remember, the better the water quality, the less a. The sensor is connected to the controller that constantly monitors and displays the tds automatic boiler blow down system level & takes the control action whenever necessary. An automated blowdown system will, on an adjustable timed basis, automatically sample the boiler water and measure the conductivity. The amount of blowdown required is directly related to the quality of the water being fed into the boiler. Blowdown package is essential for high capacity systems that operate continuously.

Source: taprogge.com

Source: taprogge.com

Controls are provided for causing blowdown when the content of dissolved solids in the boiler water reaches a first level. Conductivity, or the total dissolved solids inside the boiler, is controlled only by the boiler surface blowdown valve. Abv21i and abv40i air actuated boiler blowdown valves: An automated blowdown system will, on an adjustable timed basis, automatically sample the boiler water and measure the conductivity. Blowoff tanks for specific applications and asme code requirements.

Source: messplay.com

Source: messplay.com

Volfram offers the reliable complete solution for tds based automatic boiler blow down system. The sensor is connected to the controller that constantly monitors and displays the tds automatic boiler blow down system level & takes the control action whenever necessary. Spirax sarco installed two automated tds systems for boiler blowdown. The automatic tds (total dissolved solids) systems monitor the build up of contamination in the boilers and initiate a boiler blowdown when the level of contaminants reaches a preset threshold. The amount of blowdown necessary depends on boiler operating pressure, amount of makeup water, impurity levels in the makeup water, and the dissolved solids concentrations that a given boiler can tolerate.

Source: en.pnosan.com.tr

Source: en.pnosan.com.tr

Controls are provided for causing blowdown when the content of dissolved solids in the boiler water reaches a first level. Volfram offers reliable & complete solution for tds based automatic boiler blow down system. Boiler automation and blowdown control is important. Conductivity, or the total dissolved solids inside the boiler, is controlled only by the boiler surface blowdown valve. Surface blowdown is caused when the.

Source: industrialsteam.com

Source: industrialsteam.com

Spirax sarco us bottom blowdown systems provide efficient control of blowdown water, essential to maintaining steam quality & improve boiler efficiency. Volfram offers reliable & complete solution for tds based automatic boiler blow down system. The controllers offer latest technology and. An automated blowdown control is used when the makeup water load varies greatly or other factors contribute to difficulties in maintaining your boiler water chemistry. Scada demonstration for auto blowdown for boilers.#scada #plc #industrial_automation

Source: bryanboilers.com

Source: bryanboilers.com

The boiler zone where the accumulation causes the biggest problem is the evaporator pipes around the burners in the combustion chamber. The boiler zone where the accumulation causes the biggest problem is the evaporator pipes around the burners in the combustion chamber. The amount of blowdown necessary depends on boiler operating pressure, amount of makeup water, impurity levels in the makeup water, and the dissolved solids concentrations that a given boiler can tolerate. So remember, the better the water quality, the less a. Boiler automation and blowdown control is important.

Source: indiamart.com

Source: indiamart.com

The system that is used to prevent the problems caused by these hard accumulation compounds and to expurge hard materials from the boiler is called boiler automatic bottom blowdown systems. This helps to eliminate impurities, suspended solids, and sludge, in an effort to control the water parameters. The amount of blowdown required is directly related to the quality of the water being fed into the boiler. Scada demonstration for auto blowdown for boilers.#scada #plc #industrial_automation How to automate boiler blowdown control?

Source: sentry-equip.com

Source: sentry-equip.com

When sodium zeolite softened makeup is used, the need for boiler blowdown is usually. When sodium zeolite softened makeup is used, the need for boiler blowdown is usually. The automatic boiler bottom blowdown systems market is appropriately divided into pivotal segments according to the report. Blowdown package is essential for high capacity systems that operate continuously. Blowdown prevents buildup of harmful solids in steam boilers.

Source: icicaldaie.com

Source: icicaldaie.com

The amount of blowdown necessary depends on boiler operating pressure, amount of makeup water, impurity levels in the makeup water, and the dissolved solids concentrations that a given boiler can tolerate. Boiler blowdown system savings with automatic control system: Boiler blowdown is the process of removing water from the system. The amount of blowdown required is directly related to the quality of the water being fed into the boiler. Conductivity, or the total dissolved solids inside the boiler, is controlled only by the boiler surface blowdown valve.

Source: keepital.com

Source: keepital.com

The system that is used to prevent the problems caused by these hard accumulation compounds and to expurge hard materials from the boiler is called boiler automatic bottom blowdown systems. An automatic blowdown continuously monitors the quality of feed water as well as the quality of water inside a boiler shell and automatically opens as soon as the boiler water tds exceeds the permissible operating limit.this type of blowdown helps remove a maximum amount of dissolved solids with only minimal loss of water and heat from the boiler. Blowdown prevents buildup of harmful solids in steam boilers. The blow down occurs too often, and does not allow the system to fully. The system comprises a sensor chamber with conductivity sensor and temperature sensor, mounted in bypass to the manual blow down valve.

Source: thermaxglobal.com

Source: thermaxglobal.com

If an economical blowdown rate is to be maintained, suitable boiler water tests must be run frequently to check concentrations in the boiler water. The system includes a blowdown tank connected to the bottom of a boiler. The controllers offer latest technology and. The amount of blowdown necessary depends on boiler operating pressure, amount of makeup water, impurity levels in the makeup water, and the dissolved solids concentrations that a given boiler can tolerate. A synopsis of the industry with regards to market size concerning renumeration and volume aspects along with the current automatic boiler bottom blowdown systems market scenario is offered in the report.

Source: burnhamcommercial.com

Source: burnhamcommercial.com

The controllers offer latest technology and. Blowdown helps maintain boiler water level safety controls. An automatic blowdown continuously monitors the quality of feed water as well as the quality of water inside a boiler shell and automatically opens as soon as the boiler water tds exceeds the permissible operating limit.this type of blowdown helps remove a maximum amount of dissolved solids with only minimal loss of water and heat from the boiler. A blowdown system for controlling blowdown of a boiler such that the level of dissolved solids in the boiler is carefully controlled. Boiler blowdown system savings with automatic control system:

Source: taprogge.com

Source: taprogge.com

The sensor is connected to the controller that constantly monitors and displays the tds level takes the control. The amount of blowdown required is directly related to the quality of the water being fed into the boiler. The sensor is connected to the controller that constantly monitors and displays the tds automatic boiler blow down system level & takes the control action whenever necessary. The new automated system has reduced boiler fuel consumption by 3%. Boiler automation and blowdown control is important.

If you find this site adventageous, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title automatic boiler blowdown systems by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.