Plaster mold casting process

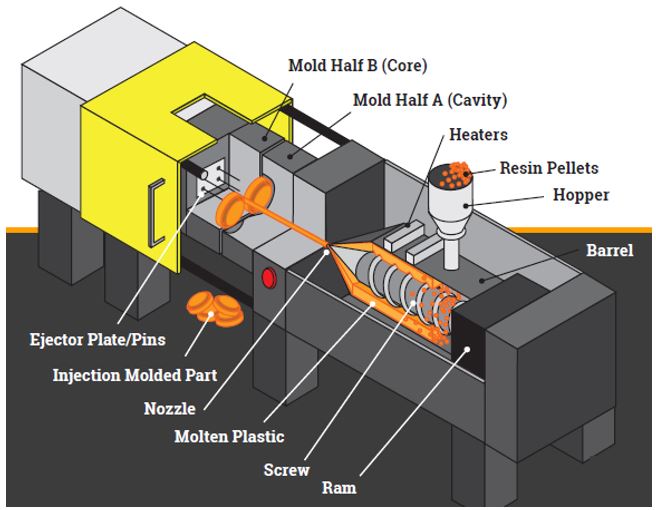

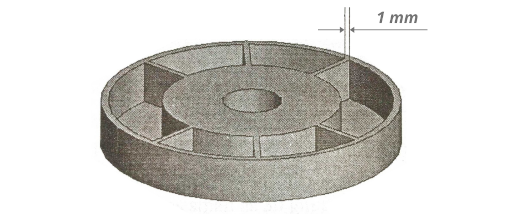

Plaster Mold Casting Process. Advantages of plaster mold casting by using plaster mold casting, the components having thickness upto 0.6 mm can be manufactured. A more unusual process, and only applicable for lower melting point alloys, the process is more expensive. The process initially plaster of paris is mixed with water just. Parting line tolerance, and 0.07 in.

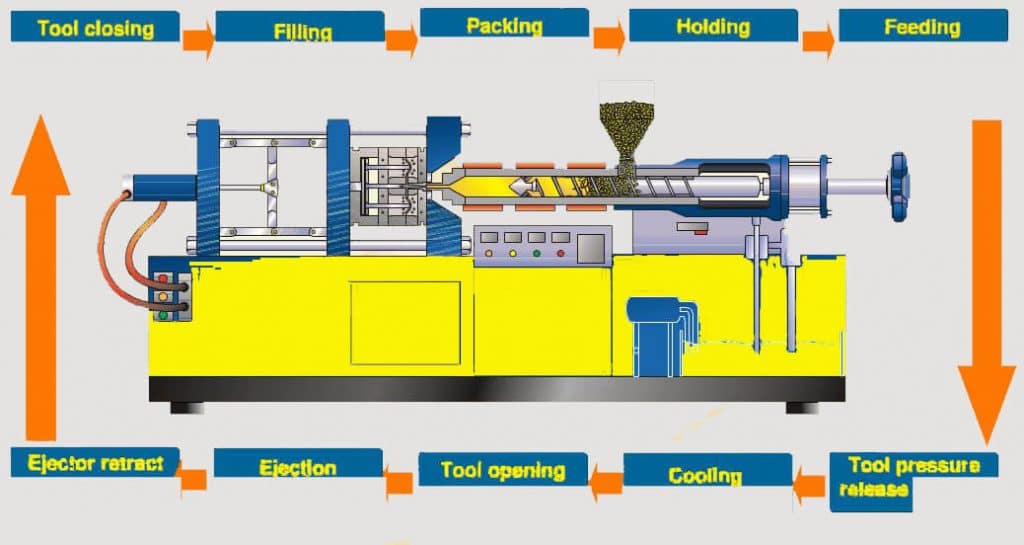

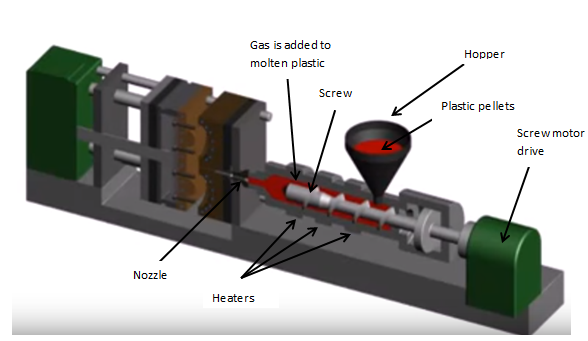

China Professinal injection mold and die casting From pf-mold.com

China Professinal injection mold and die casting From pf-mold.com

Advantages of plaster mold casting by using plaster mold casting, the components having thickness upto 0.6 mm can be manufactured. The shaw process and the unicast process. Plaster moulding process | plaster mould casting process | engineering study materialsplaster mold casting is a manufacturing process having a similar techni. Variables that affect casting quality are. These casting processes are commonly used to make. In this process, an additional 50% sand.

In sand casting, the molding material is sand, while in plaster mold casting, the molding material is plaster of paris (pop).

Good geometric accuracy can be obtained by using a. Constructed from customer drawing or cad file. After the mold is firm, the mold halves (cope and drag) are removed from the tool, carefully assembled into a complete mold, serialized, and dried. Plaster mould casting similar to sand casting, the mould is made of plaster of paris, rather than sand, and is used when an excellent surface finish and good dimensional accuracy is required. Materials worked with are aluminum, brass, bronze, zinc, and beryllium copper. Vacuuming the plaster mold cavity is another solution for this poreless structure of plaster mold.

Source: xcentricmold.com

Source: xcentricmold.com

In sand casting, the molding material is sand, while in plaster mold casting, the molding material is plaster of paris (pop). Sand is packed around the obtained polystyrene foam to create mold cavity. This video describes the process of casting in plaster from a waste mold. In industry parts such as valves, tooling, gears, and lock components may be manufactured by plaster mold casting. Plaster of paris is used to form the mold for the casting, instead of sand.

Source: youtube.com

Source: youtube.com

Negative molds are made from model. Plaster mold process casting services for the aerospace and defense industries. Negative molds are made from model. Parting line tolerance, and 0.07 in. It is a combination of plaster mold casting and investment casting.

Source: plasticmoulds.net

Source: plasticmoulds.net

Vacuum sealed moulding squeeze casting process centrifugal casting plaster moulding evaporative pattern casting ceramic shell moulding slush casting stir casting; The mold halves are extracted carefully from. Variables that affect casting quality are. A plaster mixture is poured into the tool to form the mold (die). Plaster mould casting is a type of expendable mould process, meaning the moulds are not generally reused.

Source: plasticmoulds.net

Source: plasticmoulds.net

Plaster mold casting is a manufacturing process having a similar technique to sand casting. In this process, an additional 50% sand. Plaster mold casting is a manufacturing process having a similar technique to sand casting. In expanded polystyrene molding process, the pattern of the cast product is produced from polystyrene foam. A more unusual process, and only applicable for lower melting point alloys, the process is more expensive.

Source: thomasnet.com

Source: thomasnet.com

In sand casting, the molding material is sand, while in plaster mold casting, the molding material is plaster of paris (pop). Vacuum sealed moulding squeeze casting process centrifugal casting plaster moulding evaporative pattern casting ceramic shell moulding slush casting stir casting; Plaster mold process casting services for the aerospace and defense industries. Instead of using plaster to create the mold for the metal casting, ceramic casting uses refractory ceramics for a mold material. In sand casting, the molding material is sand, while in plaster mold casting, the molding material is plaster of paris (pop).

Source: precisecast.com

Source: precisecast.com

The process initially plaster of paris is mixed with water just. Plaster mold casting is a casting process where instead of sand, plaster of paris is used as the molding aggregate. Vacuuming the plaster mold cavity is another solution for this poreless structure of plaster mold. Parting line tolerance, and 0.07 in. Negative molds are made from model.

Source: mechtechguru.com

Source: mechtechguru.com

In industry, parts such as machining cutters. Ceramic mold casting, also known ambiguously as ceramic molding, is a group of metal casting processes that use ceramics as the mold material. Variables that affect casting quality are. Negative molds are made from model. Click on the given link to see drawbacks and process parameters of plaster and ceramic mold casting process.

Source: precisecast.com

Source: precisecast.com

A more unusual process, and only applicable for lower melting point alloys, the process is more expensive. Types of casting processes : The mold halves are extracted carefully from. Parting line tolerance, and 0.07 in. These casting processes are commonly used to make.

Source: precisecast.com

Source: precisecast.com

Core plugs are made from negative molds. Good geometric accuracy can be obtained by using a. Core plugs are made from negative molds. Plaster mold casting is a manufacturing process having a similar technique to sand casting. A more unusual process, and only applicable for lower melting point alloys, the process is more expensive.

Source: online-molding.com

Source: online-molding.com

It is a combination of plaster mold casting and investment casting. The mold halves are extracted carefully from. In industry parts such as valves, tooling, gears, and lock components may be manufactured by plaster mold casting. Sand is packed around the obtained polystyrene foam to create mold cavity. The manufacturing process of ceramic mold casting is like the process of plaster mold casting but can cast materials at much higher temperatures.

Source: designtekplastics.com

Source: designtekplastics.com

In industry parts such as valves, tooling, gears, and lock components may be manufactured by plaster mold casting. ‘antioch process’ can be utilized to prevent the poreless structure of plaster. Negative molds are made from model. This process is suitable for both prototype and short run production quantities of aluminum and. Advantages of plaster mold casting by using plaster mold casting, the components having thickness upto 0.6 mm can be manufactured.

Source: knordslearning.com

Source: knordslearning.com

Core plugs are made from negative molds. Two main categories of metal casting processes. Manufacturing of complex shapes is possible at less cost, because this process produces minimum scrap material. Parting line tolerance, and 0.07 in. It is a combination of plaster mold casting and investment casting.

Source: icharts.net

Source: icharts.net

In expanded polystyrene molding process, the pattern of the cast product is produced from polystyrene foam. There are two types of ceramic mold casting: Negative molds are made from model. It is a combination of plaster mold casting and investment casting. ‘antioch process’ can be utilized to prevent the poreless structure of plaster.

Source: aireplastics.com

Source: aireplastics.com

In sand casting, the molding material is sand, while in plaster mold casting, the molding material is plaster of paris (pop). ‘antioch process’ can be utilized to prevent the poreless structure of plaster. In industry, parts such as machining cutters. It is part of the nasher�s materials and process teaching resource designed to desc. In this process, an additional 50% sand.

Source: cdn-inc.com

Source: cdn-inc.com

In industry, parts such as machining cutters. A gravity pour method of filling the cavity is used. Types of casting processes : Metals that don’t contain iron. Plaster mold casting process 00 rectangle hump/slump $34 plaster of paris is calcined gypsum, which is a fine powder selection of 20+ molds, ranging from thimbles and small figurines to large planters/pots with composimold, making molds and plaster castings is really easy with composimold, making molds and plaster castings is really easy.

Source: cdn-inc.com

Source: cdn-inc.com

Small castings of 30 gram as well as large castings of 45 kilograms can also be manufactured by using a plaster mold casting process. Variables that affect casting quality are. Constructed from customer drawing or cad file. Plaster moulding process | plaster mould casting process | engineering study materialsplaster mold casting is a manufacturing process having a similar techni. The mold halves are extracted carefully from.

Source: polychem-usa.com

Source: polychem-usa.com

Manufacturing of complex shapes is possible at less cost, because this process produces minimum scrap material. Working specifications include up to 500 sq. What is plaster mold casting? In this process, an additional 50% sand. Core plugs are made from negative molds.

Source: pf-mold.com

Source: pf-mold.com

This process is suitable for both prototype and short run production quantities of aluminum and. Constructed from customer drawing or cad file. Types of casting processes : This slurry is sprayed on the polished surfaces of the pattern halves (usually brass). Click on the given link to see drawbacks and process parameters of plaster and ceramic mold casting process.

If you find this site good, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title plaster mold casting process by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.