Post heating welded metals

Post Heating Welded Metals. This temperature is held for at least 1 hour per inch [25mm] of material thickness. Tensile testing of welds in place with weld metal, heat affected zone (haz), and base metal, allows an overall strength to be. The temperature ranges from 595˚c to 775˚c depending upon the properties of the metal/material. When welding ferritic stainless steel, preheat should be limited to anywhere between 300 and 450f and applied only to the high carbon ferritic stainless like 430, 434m 442, or 446.

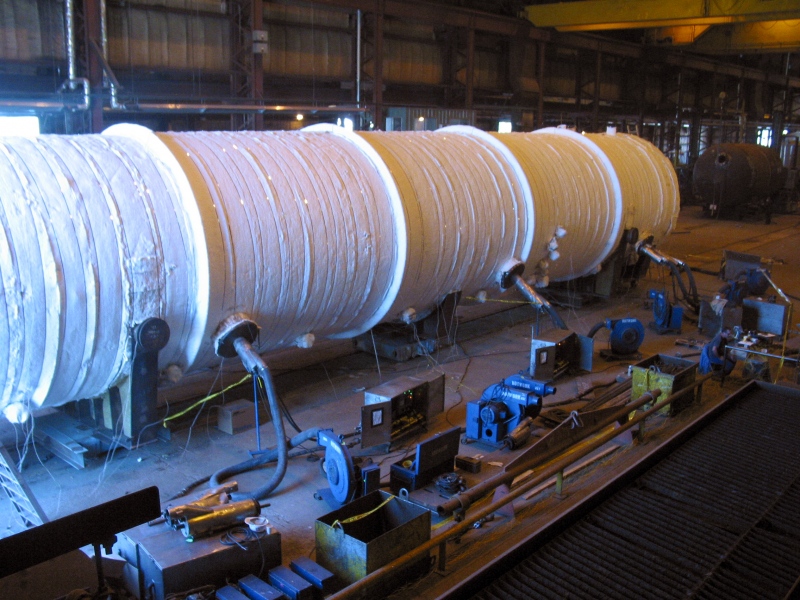

380V 3Phase Post Weld Heat Treatment Equipment For Metal Quenching From inductionheating-machine.com

380V 3Phase Post Weld Heat Treatment Equipment For Metal Quenching From inductionheating-machine.com

It is easy to retain the residual martensite structure in the welded joint. Tensile testing of welds in place with weld metal, heat affected zone (haz), and base metal, allows an overall strength to be. Post weld heat treatment tempering is therefore recommended to be around 30°c lower than the temper of the base metal. Image of a typical 430 stainless steel plate. Post weld heat treatment is a controlled heat treatment method in that welded components (welded material) are reheated in a furnace or localized. The heating rate is determined and controlled by the type of material thickness.

Tensile testing of welds in place with weld metal, heat affected zone (haz), and base metal, allows an overall strength to be.

Post weld heat treatment can be done after the weld has cooled, this can be stress relieving, annealing, or normalizing, and is usually performed to a procedure. Post weld heat treatment tempering is therefore recommended to be around 30°c lower than the temper of the base metal. Image of a typical 430 stainless steel plate. See answer (1) best answer. Stress relief after welding may be necessary to reduce the risk of brittle fracture, avoid subsequent distortion on machining, or. Tensile testing of welds in place with weld metal, heat affected zone (haz), and base metal, allows an overall strength to be.

Source: youtube.com

Source: youtube.com

Welding two different materials together may change the structure of the original metals, and a pwht may be required. Post weld heat treatment tempering is therefore recommended to be around 30°c lower than the temper of the base metal. Tensile testing of welds in place with weld metal, heat affected zone (haz), and base metal, allows an overall strength to be. If the temperature is too high, it exceeds the end temperature of martensite transformation. Post heating is not required for all metal materials during welding.

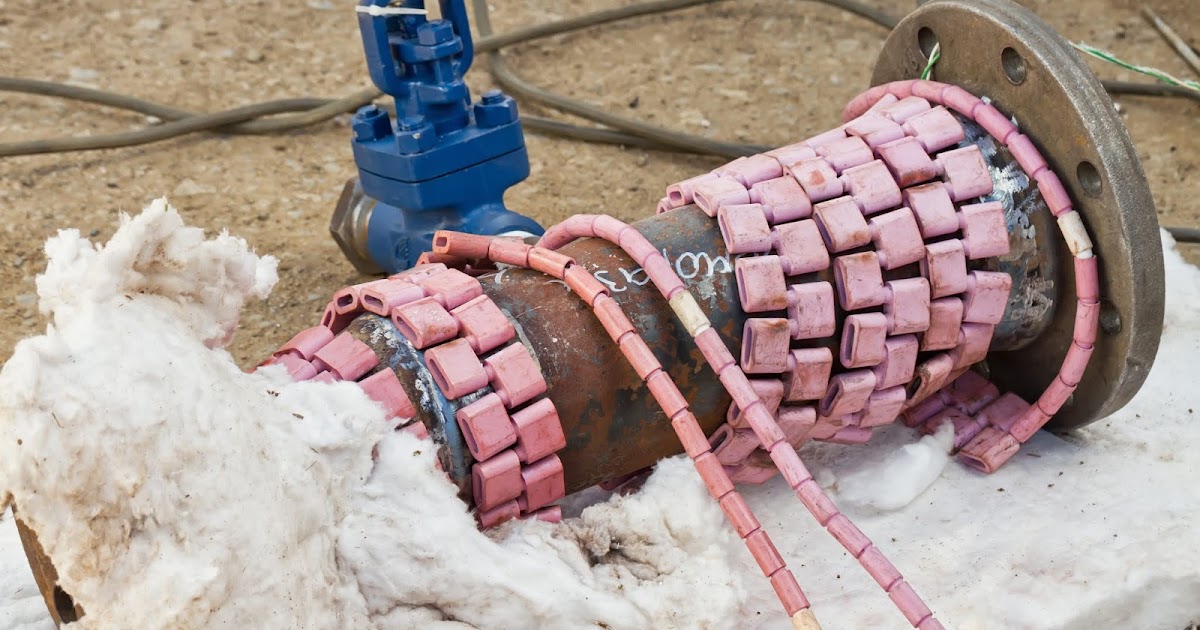

Source: blog.hotfoilehs.com

Source: blog.hotfoilehs.com

Philippa moore, geoff booth, in the welding engineer s guide to fracture and fatigue, 2015. The post heat temperature is too low, and the effect of hydrogen elimination is not good. Most large and complex shaped structures cannot be subjected to a normalizing pwht. Welding two different materials together may change the structure of the original metals, and a pwht may be required. Stress relief after welding may be necessary to reduce the risk of brittle fracture, avoid subsequent distortion on machining, or.

Source: indiamart.com

Source: indiamart.com

The temperature ranges from 595˚c to 775˚c depending upon the properties of the metal/material. The heating rate is determined and controlled by the type of material thickness. Welding two different materials together may change the structure of the original metals, and a pwht may be required. Please note that using a post weld heat treatment tempering temperature above that of the base metal will weaken the base metal. It does not reduce these levels to zero, however, and, even in a very well controlled thermal cycle, the levels of final residual stress are unlikely to be much below.

Source: blog.hotfoilehs.com

Source: blog.hotfoilehs.com

Post weld heat treatment is a controlled heat treatment method in that welded components (welded material) are reheated in a furnace or localized. Tensile testing of welds in place with weld metal, heat affected zone (haz), and base metal, allows an overall strength to be. It is often referred to as being any heat treatment performed after welding; See answer (1) best answer. Briskheat bwh heavy insulated fiberglass heating tapes can deliver heat up to 1400°f (760°c).

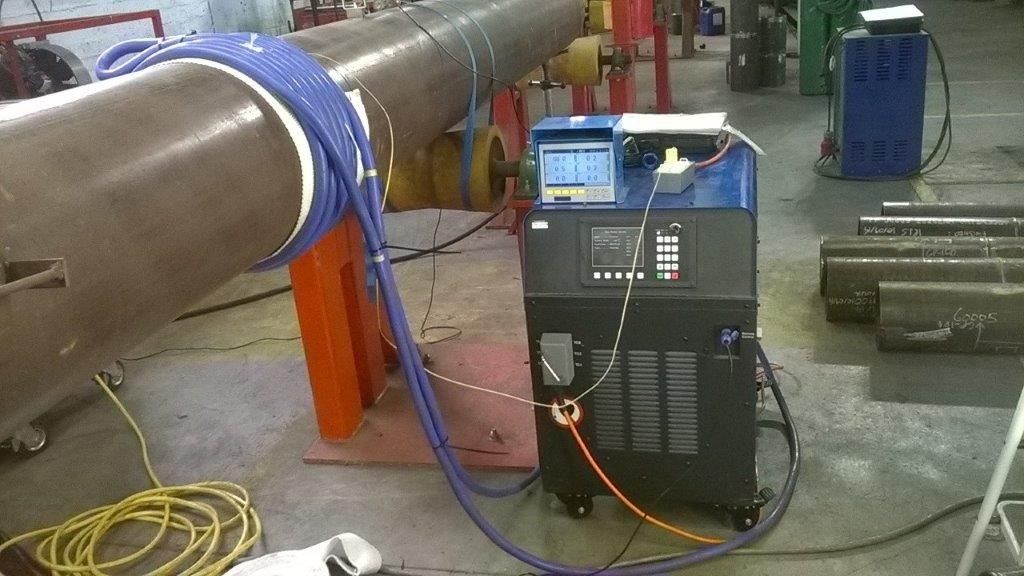

Source: inductionheating-machine.com

Source: inductionheating-machine.com

Post weld heat treatment (pwht) is a controlled process in which a material that has been welded is reheated to a temperature below its lower critical transformation temperature, and then it is held at that temperature for a specified amount of time. They have a high watt density of 13.1 w/in² (2.0 w/cm²) which ensures a rapid thermal response and even distribution of heat. Briskheat bwh heavy insulated fiberglass heating tapes can deliver heat up to 1400°f (760°c). This leads to metastable phases in weld metal region. Welding two different materials together may change the structure of the original metals, and a pwht may be required.

Source: hotwork.com

Source: hotwork.com

Welding two different materials together may change the structure of the original metals, and a pwht may be required. The preheat purpose is to prevent delayed cracking and help in removing hydrogen buildup. It is often referred to as being any heat treatment performed after welding; Recommendations on post weld heat treatment (pwht) are usually dependent upon specific alloys and. They have a high watt density of 13.1 w/in² (2.0 w/cm²) which ensures a rapid thermal response and even distribution of heat.

Source: dw-inductionheater.com

Source: dw-inductionheater.com

Philippa moore, geoff booth, in the welding engineer s guide to fracture and fatigue, 2015. Controlling cooling temperatures can increase rather than reduce the strength. Post weld heat treatment can be done after the weld has cooled, this can be stress relieving, annealing, or normalizing, and is usually performed to a procedure. The heating rate is determined and controlled by the type of material thickness. Preheat, as defined within the aws standard welding terms and definition, is “the heat applied to the base metal or substrate to attain and maintain preheat temperature”.

Source: rem-teh.com

Source: rem-teh.com

Please note that using a post weld heat treatment tempering temperature above that of the base metal will weaken the base metal. It is easy to retain the residual martensite structure in the welded joint. If the temperature is too high, it exceeds the end temperature of martensite transformation. Controlling cooling temperatures can increase rather than reduce the strength. Briskheat bwh heavy insulated fiberglass heating tapes can deliver heat up to 1400°f (760°c).

Source: inductionheating-machine.com

Source: inductionheating-machine.com

Image of a typical 430 stainless steel plate. [noun] the process of heating a metal after welding in order to decrease the rate of cooling to room temperature. Image of a typical 430 stainless steel plate. It is easy to retain the residual martensite structure in the welded joint. When welding ferritic stainless steel, preheat should be limited to anywhere between 300 and 450f and applied only to the high carbon ferritic stainless like 430, 434m 442, or 446.

Source: welderdestiny.com

Source: welderdestiny.com

See answer (1) best answer. Image of a typical 430 stainless steel plate. Stress relief after welding may be necessary to reduce the risk of brittle fracture, avoid subsequent distortion on machining, or. Post weld heat treatment tempering is therefore recommended to be around 30°c lower than the temper of the base metal. Recommendations on post weld heat treatment (pwht) are usually dependent upon specific alloys and.

Source: gottisrl.com

Source: gottisrl.com

Post weld heat treatment tempering is therefore recommended to be around 30°c lower than the temper of the base metal. Philippa moore, geoff booth, in the welding engineer s guide to fracture and fatigue, 2015. The heating rate is determined and controlled by the type of material thickness. Please note that using a post weld heat treatment tempering temperature above that of the base metal will weaken the base metal. See answer (1) best answer.

Source: oiltubulars.com

Source: oiltubulars.com

The preheat purpose is to prevent delayed cracking and help in removing hydrogen buildup. Image of a typical 430 stainless steel plate. They have a high watt density of 13.1 w/in² (2.0 w/cm²) which ensures a rapid thermal response and even distribution of heat. Briskheat bwh heavy insulated fiberglass heating tapes can deliver heat up to 1400°f (760°c). The heating rate is determined and controlled by the type of material thickness.

Source: blog.hotfoilehs.com

Source: blog.hotfoilehs.com

The thicker the weld, the higher the thermal gradient which may contribute to higher residual stress on the primary material making a pwht necessary. Recommendations on post weld heat treatment (pwht) are usually dependent upon specific alloys and. Post weld heat treatment is a controlled heat treatment method in that welded components (welded material) are reheated in a furnace or localized. In general, you must heat the part high enough to allow hydrogen to diffuse out of the weld and haz but not high enough to create any type of microstructural change. Welding two different materials together may change the structure of the original metals, and a pwht may be required.

Source: bitspvtltd.com

Source: bitspvtltd.com

Welding two different materials together may change the structure of the original metals, and a pwht may be required. The heating rate is determined and controlled by the type of material thickness. Post weld heat treatment (pwht) is a controlled process in which a material that has been welded is reheated to a temperature below its lower critical transformation temperature, and then it is held at that temperature for a specified amount of time. Controlling cooling temperatures can increase rather than reduce the strength. They have a high watt density of 13.1 w/in² (2.0 w/cm²) which ensures a rapid thermal response and even distribution of heat.

Source: indiamart.com

Source: indiamart.com

The temperature ranges from 595˚c to 775˚c depending upon the properties of the metal/material. However, within the oil, gas, petrochemical and. The heating rate is determined and controlled by the type of material thickness. Post heating is not required for all metal materials during welding. Post weld heat treatment (pwht) is a controlled process in which a material that has been welded is reheated to a temperature below its lower critical transformation temperature, and then it is held at that temperature for a specified amount of time.

Source: jst-group.com

Source: jst-group.com

[noun] the process of heating a metal after welding in order to decrease the rate of cooling to room temperature. So this detrimental effect should be minimized by heat treatment. Post weld heat treatment (pwht) is a controlled process in which a material that has been welded is reheated to a temperature below its lower critical transformation temperature, and then it is held at that temperature for a specified amount of time. The preheat purpose is to prevent delayed cracking and help in removing hydrogen buildup. If the temperature is too high, it exceeds the end temperature of martensite transformation.

Source: pipingsystems.com

Source: pipingsystems.com

Post weld heat treatment tempering is therefore recommended to be around 30°c lower than the temper of the base metal. The preheat purpose is to prevent delayed cracking and help in removing hydrogen buildup. Preheat, as defined within the aws standard welding terms and definition, is “the heat applied to the base metal or substrate to attain and maintain preheat temperature”. Recommendations on post weld heat treatment (pwht) are usually dependent upon specific alloys and. Post weld heat treatment (pwht) is a controlled process in which a material that has been welded is reheated to a temperature below its lower critical transformation temperature, and then it is held at that temperature for a specified amount of time.

Source: sylmasta.com

Source: sylmasta.com

Post heating is not required for all metal materials during welding. It does not reduce these levels to zero, however, and, even in a very well controlled thermal cycle, the levels of final residual stress are unlikely to be much below. Image of a typical 430 stainless steel plate. In general, you must heat the part high enough to allow hydrogen to diffuse out of the weld and haz but not high enough to create any type of microstructural change. Post heating is not required for all metal materials during welding.

If you find this site serviceableness, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title post heating welded metals by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.