Potential hazards relating to arc welding are

Potential Hazards Relating To Arc Welding Are. Pointed at the base of the fire. Always ensure that the respirator is recommended for the welding work you are doing. Potential hazards relating to arc welding are. Similarly overexposure to manginess can cause malfunction of central.

welding From slideshare.net

welding From slideshare.net

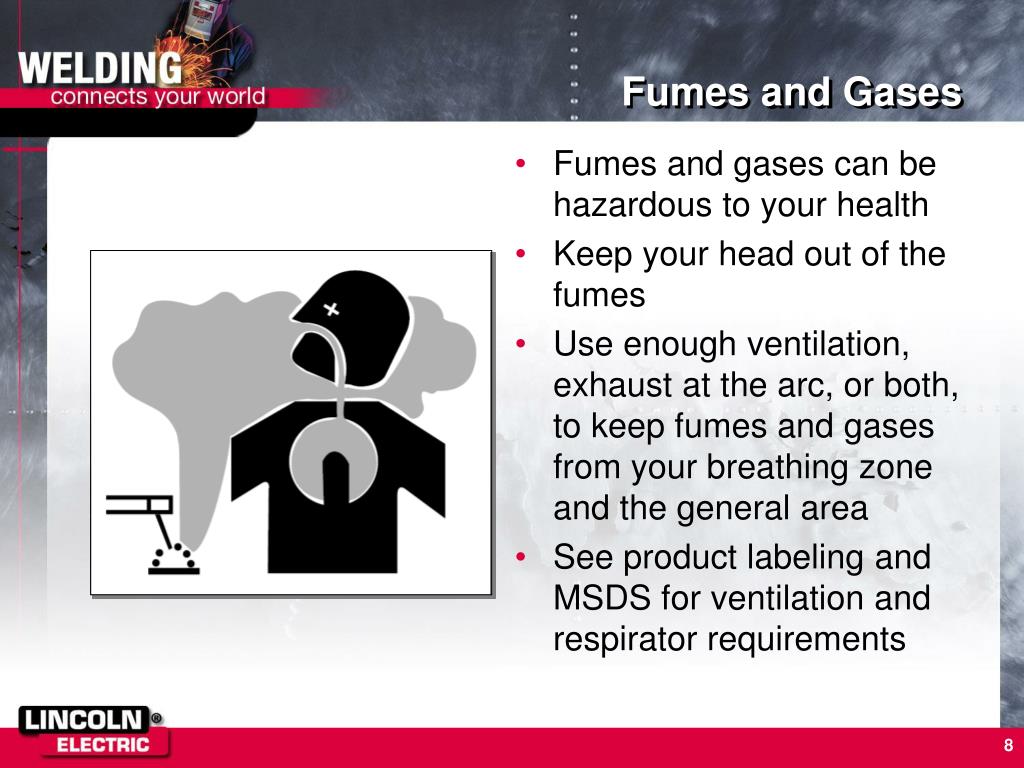

The most common welding fumes are chromium, iron, manganese and nickel etc contributed by both electrodes and base metals. Arc welding is a safe occupation when proper precautions are taken. The specific potential health effects related to the welding consumable product being used can be. Arc welding techniques are still the most common. The electric arc welder remains one of our most useful and timesaving pieces of shop equipment. Some of the welding hazards can be prevented by proper personal protective equipment (ppe), training, engineering controls, and work practices.

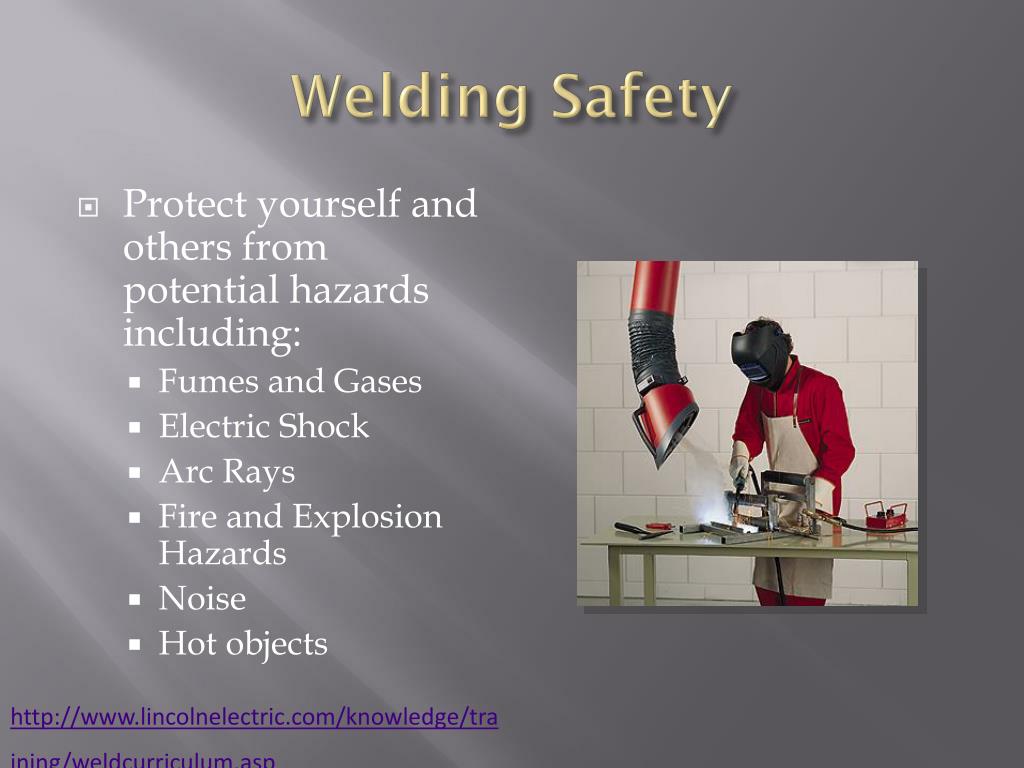

But, if safety measures are ignored, welders face an array of hazards which can be potentially dangerous, including electric shock, fumes and gases, fire and explosions.

Electric shock is the most serious hazard posed by welding and can result in serious injuries and fatalities, either through a direct shock or from a fall from height. Always ensure that the respirator is recommended for the welding work you are doing. Potential hazards relating to arc welding are. Coatings and paints on the metal or electrode coatings; Pointed at the base of the fire. Being overexposed to welding fumes and gases can be very hazardous to your health—welding fumes contain.

Source: slideshare.net

Source: slideshare.net

What type of fire extinguisher should be used on electrical fires. Wearing appropriate ppe like welding helmet and goggles to protect workers’ eyes and head from hot slag, sparks, intense light, and chemical burns. But, if safety measures are ignored, welders face an array of hazards which can be potentially dangerous, including electric shock, fumes and gases, fire and explosions and more. What type of fire extinguisher should be used on electrical fires. Pointed at the base of the fire.

Source: slideserve.com

Source: slideserve.com

The electric arc welder remains one of our most useful and timesaving pieces of shop equipment. The most common welding fumes are chromium, iron, manganese and nickel etc contributed by both electrodes and base metals. Coatings and paints on the metal or electrode coatings; Welding workers should remain in the work area for at least 30 minutes after finishing welding to ensure. The hazards associated with this process are highlighted.

Source: slideshare.net

Source: slideshare.net

The resistance in gas (think about the difficulty. All of above (in arc welding process operator is exposed to fumes , el. The electric arc welder remains one of our most useful and timesaving pieces of shop equipment. However, many fully automatic electronic welding process are also carried in industry. Keep in mind that all welding operations, either it is shielded metal arc welding, gas.

Source: slideserve.com

Source: slideserve.com

However, many fully automatic electronic welding process are also carried in industry. However, many fully automatic electronic welding process are also carried in industry. Welders should not touch the metal parts of the electrode holder with skin or wet clothing. To help keep welders safe, organizations such as the american conference of governmental industrial. Potential hazards related to arc welding are radiation fumes toxic gases all of the above question 2 purpose of the flux in arc welding is prevent the formation of oxides and other contaminants or to dissolve them.

Source: slideserve.com

Source: slideserve.com

4 potential welding safety hazards to avoid electric shock. Pointed at the base of the fire. Potential hazards relating to arc welding are. Arc welding is based on the creation of an electrical circuit, and a “break” in the electrical circuit, where the electricity is forced to travel through a gas (that becomes ionized in this process). Welders can suffer from asthma and lung cancer if overexposed to chromium and nickel.

Source: safetywarehouse.eu

Source: safetywarehouse.eu

Welding fumes and gases has been reported dangerous if overexposed. Fluxes used in certain welding and brazing processes produce vapors irritating to the eyes, nose, throat, and lungs. When using a fire extinguisher to extinguish a fire, it should be. Welding workers should remain in the work area for at least 30 minutes after finishing welding to ensure. Electric shock is one of the most serious and most immediate risks on the work site.

Source: pinterest.co.kr

Source: pinterest.co.kr

Moved up and down to. But, if safety measures are ignored, welders face an array of hazards which can be potentially dangerous, including electric shock, fumes and gases, fire and explosions. Welding workers should remain in the work area for at least 30 minutes after finishing welding to ensure. Welders should not touch the metal parts of the electrode holder with skin or wet clothing. Here are some vital welding safety measures to ensure safety protection and avoid the most common welding hazards.

Source: supasign.co.uk

Source: supasign.co.uk

The wrong and right ways to carry out arc welding processes are shown schematically in the figure at the end of this page. The welding arc creates extreme temperatures, and may pose a significant fire and explosions hazard if safe practices are not followed. Therefore, when welding, you are at risk of experiencing an electric shock. Welding fumes and gases has been reported dangerous if overexposed. But, if safety measures are ignored, welders face an array of hazards which can be potentially dangerous, including electric shock, fumes and gases, fire and explosions.

Source: safetysignsservice.com.au

Source: safetysignsservice.com.au

Welders can suffer from asthma and lung cancer if overexposed to chromium and nickel. Arc welding is a safe occupation when proper precautions are taken. During the arc welding process, live electrical circuits are used to create a pool of molten metal. Welding fumes and gases generally come from the following sources: Arc welding is a safe occupation when proper precautions are taken.

Source: safetysignsandppe.co.uk

Source: safetysignsandppe.co.uk

During the arc welding process, live electrical circuits are used to create a pool of molten metal. The hazards associated with this process are highlighted. Electric shock is the most serious hazard posed by welding and can result in serious injuries and fatalities, either through a direct shock or from a fall from height. Welding fumes and gases has been reported dangerous if overexposed. Welding workers should remain in the work area for at least 30 minutes after finishing welding to ensure.

Source: slideserve.com

Source: slideserve.com

Here are some vital welding safety measures to ensure safety protection and avoid the most common welding hazards. Regarding safe welding practices, the principal hazards are associated. The hazards associated with this process are highlighted. While the welding arc may reach temperatures of 10,000 degrees fahrenheit, the real danger is not from the arc itself, but rather the intense heat near the arc and the heat, sparks and spatter created by the arc. Therefore, when welding, you are at risk of experiencing an electric shock.

Source: slideserve.com

Source: slideserve.com

Welding safety hazards and precautions welding methods. Potential hazards related to arc welding are radiation fumes toxic gases all of the above question 2 purpose of the flux in arc welding is prevent the formation of oxides and other contaminants or to dissolve them. Base material being welded or the filler material used. Five potential welding safety hazards to avoid. The wrong and right ways to carry out arc welding processes are shown schematically in the figure at the end of this page.

Source: slideserve.com

Source: slideserve.com

When using a fire extinguisher to extinguish a fire, it should be. But, if safety measures are ignored, welders face an array of hazards which can be potentially dangerous, including electric shock, fumes and gases, fire and explosions and more. Almost every farm, ranch, and vocational agriculture shop is equipped with one or more welders which are used for fabrication, repair, and/or educational programs. Pointed at the base of the fire. Electric shock is the most serious hazard posed by welding and can result in serious injuries and fatalities, either through a direct shock or from a fall from height.

Source: slideserve.com

Source: slideserve.com

The electric arc welder remains one of our most useful and timesaving pieces of shop equipment. However, many fully automatic electronic welding process are also carried in industry. Coatings and paints on the metal or electrode coatings; Welding workers should remain in the work area for at least 30 minutes after finishing welding to ensure. Electric shock is the most serious hazard posed by welding and can result in serious injuries and fatalities, either through a direct shock or from a fall from height.

Source: slideserve.com

Source: slideserve.com

When using a fire extinguisher to extinguish a fire, it should be. Keep in mind that all welding operations, either it is shielded metal arc welding, gas. When using a fire extinguisher to extinguish a fire, it should be. Welding fumes and gases has been reported dangerous if overexposed. Some of the welding hazards can be prevented by proper personal protective equipment (ppe), training, engineering controls, and work practices.

Source: k3lh.com

Source: k3lh.com

Welding fumes and gases generally come from the following sources: Arc welding is based on the creation of an electrical circuit, and a “break” in the electrical circuit, where the electricity is forced to travel through a gas (that becomes ionized in this process). Electric shock is one of the most serious and most immediate risks on the work site. Being overexposed to welding fumes and gases can be very hazardous to your health—welding fumes contain. 4 potential welding safety hazards to avoid electric shock.

Source: accuform.com

Source: accuform.com

During the arc welding process, live electrical circuits are used to create a pool of molten metal. Arc welding is a safe occupation when proper precautions are taken, but if safety measures are ignored, welders face an array of hazards that can be potentially dangerous, including electric shock, fumes and gases, fire, explosions, and more. Five potential welding safety hazards to avoid. The process may be manual metallic arc (mma), metal. Welding is usually only one of a number of processes required to fabricate or manufacture.

Source: slideserve.com

Source: slideserve.com

Arc welding techniques are still the most common. While the welding arc may reach temperatures of 10,000 degrees fahrenheit, the real danger is not from the arc itself, but rather the intense heat near the arc and the heat, sparks and spatter created by the arc. Welders should not touch the metal parts of the electrode holder with skin or wet clothing. The most common welding fumes are chromium, iron, manganese and nickel etc contributed by both electrodes and base metals. Arc welding techniques are still the most common.

If you find this site helpful, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title potential hazards relating to arc welding are by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.