Printed circuit boards are typically made out of

Printed Circuit Boards Are Typically Made Out Of. Interestingly, the end product will be a plastic sheet with a photo negative of the pcb in an ink that is dark black. Circuit boards, or printed circuit boards (pcbs), are standard components in modern electronic devices and products. The first step of the pcb manufacturing process is to make the substrate. At that, you would go through a final silkscreen stage to mark out all the board’s elements.

Inventors Build Your Own Printed Circuit Boards Online From lowcostpcbassembly.wordpress.com

Inventors Build Your Own Printed Circuit Boards Online From lowcostpcbassembly.wordpress.com

This type of pcb is easy to design and. The design to be printed is known beforehand. The black areas show where the conductive materials. One side of the base’s material is coated with a thin metal plating, such as copper, after which point a protective solder mask is typically applied. There are several types of printed circuit boards made from a wide range of materials. When making a led circuit board, you should be fami.

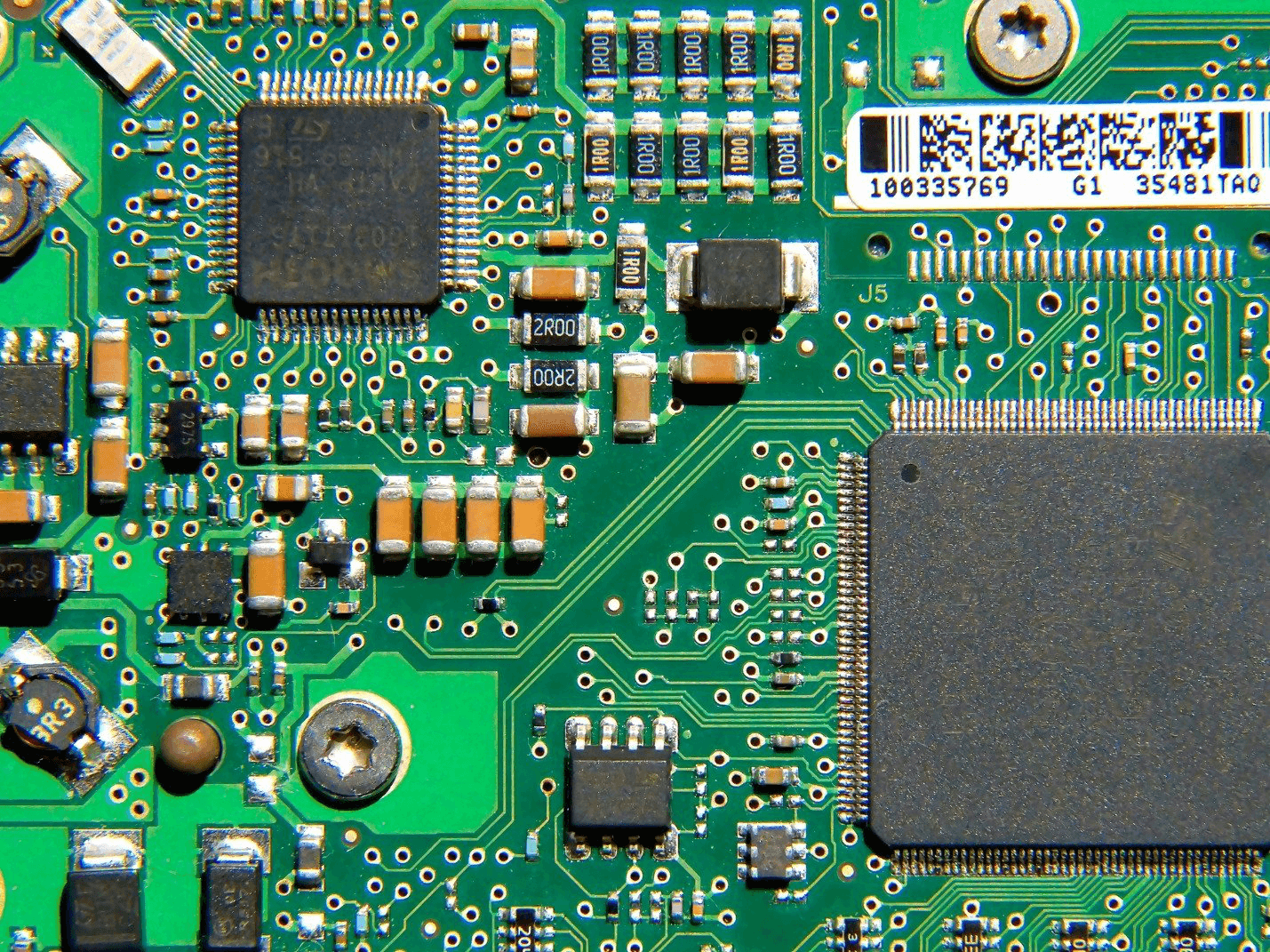

Printed circuit board (pcb) is a thin plate on which chips & electronic components are placed.

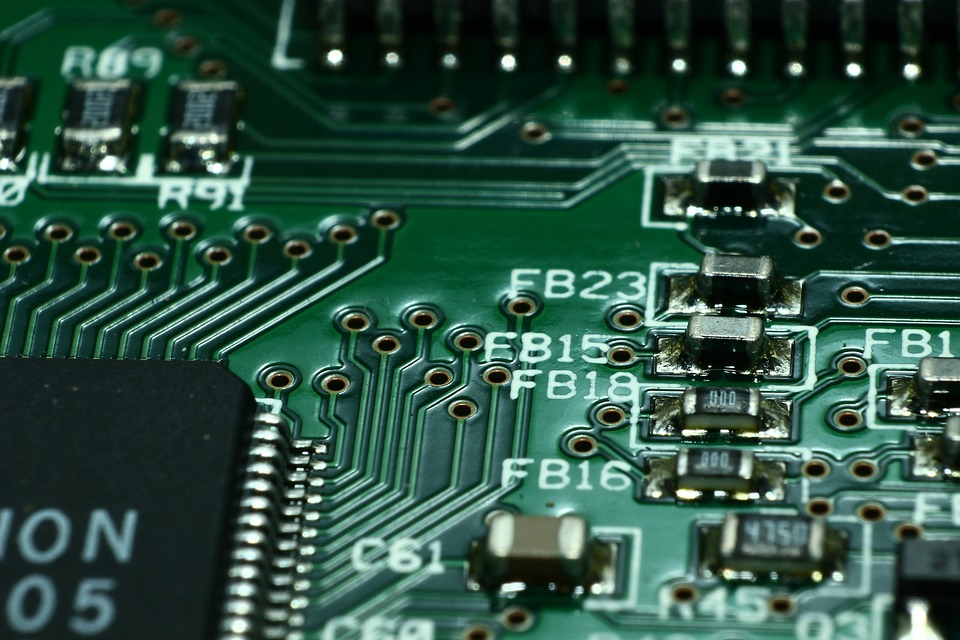

What are printed circuit boards typically made out of? The substrate is created by combining woven glass fibre and epoxy resin and then rolled into the desired thickness. I need to figure out what th. A printed circuit board (pcb) or printed wiring board (pwb) is a laminated sandwich structure of conductive and insulating layers.pcbs have two complementary functions. Since the 1900s, printed circuit boards have evolved to meet quality, performance demands, and precision for modern technology. These panels are stacked in alternating.

Source: theindependentcollective.net

Source: theindependentcollective.net

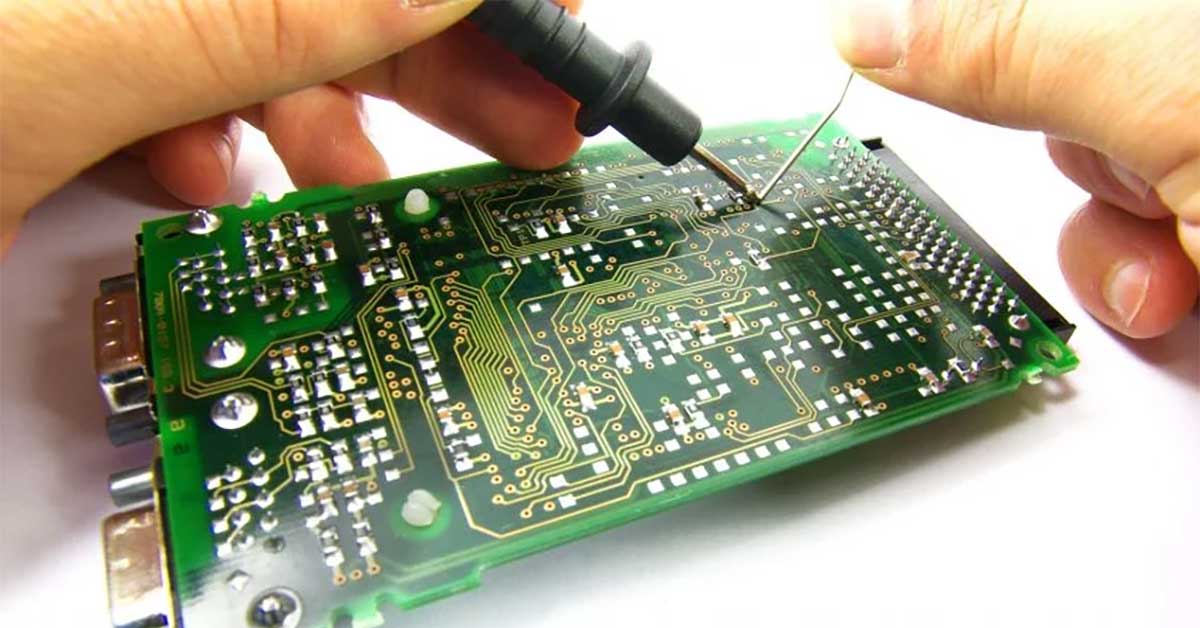

This pcb is made of one, single layer of a base substrate. The first step of the pcb manufacturing process is to make the substrate. The first is to affix electronic components in designated locations on the outer layers by means of soldering.the second is to provide reliable electrical connections (and also reliable open circuits) between. What are printed circuit boards typically made out of? This pcb is made of one, single layer of a base substrate.

Source: fischco.org

Source: fischco.org

The pcb is then exposed to uv light which passes through the clear sections of the board to harden them to ensure they are not conductive. Glass is the mechanical substrate that holds the resin in place. The pcb is then exposed to uv light which passes through the clear sections of the board to harden them to ensure they are not conductive. When making a led circuit board, you should be fami. The five basic components of a standard printed circuit board are:

Source: exceptionpcb.com

Source: exceptionpcb.com

The first is to affix electronic components in designated locations on the outer layers by means of soldering.the second is to provide reliable electrical connections (and also reliable open circuits) between. The inner part of flexible printed circuit board material comprises epoxy resin and fiberglass that are also. When people talk about home hack projects that can be put together in a workshop, a lot de. Circuit boards, or printed circuit boards (pcbs), are standard components in modern electronic devices and products. The pcb is then exposed to uv light which passes through the clear sections of the board to harden them to ensure they are not conductive.

Source: cctc-hfpcb.com

Source: cctc-hfpcb.com

These panels are stacked in alternating. What does a pcb do. Every printed circuit board is manufactured to connect and support a particular circuit, and so all the tracks, pads, vias, etc., are calculated and designed in advance. The first is to affix electronic components in designated locations on the outer layers by means of soldering.the second is to provide reliable electrical connections (and also reliable open circuits) between. I was thinking of this theoretical circuit making system.

Source: sciencelearn.org.nz

Source: sciencelearn.org.nz

Interestingly, the end product will be a plastic sheet with a photo negative of the pcb in an ink that is dark black. The result is the manufacturer will be able to print the pcbs that they need, and the films will also be used to image them. The inner part of flexible printed circuit board material comprises epoxy resin and fiberglass that are also. The printed circuit board manufacturing process. The pcb bakes in an industrial oven to melt the solder, which joins the connections.

Source: electronicslovers.com

Source: electronicslovers.com

Since the 1900s, printed circuit boards have evolved to meet quality, performance demands, and precision for modern technology. When making a led circuit board, you should be fami. Here�s more information about how. One side of the base’s material is coated with a thin metal plating, such as copper, after which point a protective solder mask is typically applied. Printed circuit boards are typically made out of.

Source: fuzeplay.io

Source: fuzeplay.io

The pcb bakes in an industrial oven to melt the solder, which joins the connections. Prepreg is a thin glass fabric that is coated with resin and dried in a special machine called a prepreg processor. Then i would fill the paste in an ink jet printer. The design to be printed is known beforehand. Using laser printers, the manufacturer creates negative photo films of the circuit board and components.

Source: pcbdirectory.com

Source: pcbdirectory.com

The first step of the pcb manufacturing process is to make the substrate. The substrate is created by combining woven glass fibre and epoxy resin and then rolled into the desired thickness. The five basic components of a standard printed circuit board are: When making a led circuit board, you should be fami. I would get some sort of powdered or granular metal (possibly lead) and mix it with small amounts of water.

Source: extremetech.com

Source: extremetech.com

When making a led circuit board, you should be fami. Generally, printed circuit boards are the heart of modern electrical products. This process primarily deals with printing of the figure on the copper foil. The final photo is in black ink and each layer of the printed circuit board has their own film sheet. Using laser printers, the manufacturer creates negative photo films of the circuit board and components.

Source: pinterest.com

Source: pinterest.com

I would get some sort of powdered or granular metal (possibly lead) and mix it with small amounts of water. This process prepares for the creation of the printed circuit board. This pcb is made of one, single layer of a base substrate. When making a led circuit board, you should be fami. These panels are stacked in alternating.

Source: youtube.com

Source: youtube.com

Prepreg is a thin glass fabric that is coated with resin and dried in a special machine called a prepreg processor. This process prepares for the creation of the printed circuit board. Generally, printed circuit boards are the heart of modern electrical products. I was thinking of this theoretical circuit making system. At that, you would go through a final silkscreen stage to mark out all the board’s elements.

Source: svtronics.com

Source: svtronics.com

The black areas show where the conductive materials. Generally, printed circuit boards are the heart of modern electrical products. There are several types of printed circuit boards made from a wide range of materials. I would get some sort of powdered or granular metal (possibly lead) and mix it with small amounts of water. Since the 1900s, printed circuit boards have evolved to meet quality, performance demands, and precision for modern technology.

Source: copiermachinesplano.com

Source: copiermachinesplano.com

The first step of the pcb manufacturing process is to make the substrate. The first step of the pcb manufacturing process is to make the substrate. Interestingly, the end product will be a plastic sheet with a photo negative of the pcb in an ink that is dark black. Circuit boards, or printed circuit boards (pcbs), are standard components in modern electronic devices and products. The pcb bakes in an industrial oven to melt the solder, which joins the connections.

Source: pinterest.com

Source: pinterest.com

When people talk about home hack projects that can be put together in a workshop, a lot de. After the pcb has been exposed to uv, the board is then washed. The five basic components of a standard printed circuit board are: Circuit boards, or printed circuit boards (pcbs), are standard components in modern electronic devices and products. When making a led circuit board, you should be fami.

Source: acdi.com

Source: acdi.com

The printed circuit board manufacturing process. Making a led (light emitting diode) circuit board is a good exercise for those new to electronics. Printed circuit boards are typically made out of. The inner part of flexible printed circuit board material comprises epoxy resin and fiberglass that are also. Generally, printed circuit boards are the heart of modern electrical products.

Source: spectrum.ieee.org

Source: spectrum.ieee.org

The substrate is created by combining woven glass fibre and epoxy resin and then rolled into the desired thickness. See answer (1) best answer. The final photo is in black ink and each layer of the printed circuit board has their own film sheet. This type of pcb is easy to design and. The substrate is created by combining woven glass fibre and epoxy resin and then rolled into the desired thickness.

Source: internetvibes.net

Source: internetvibes.net

When making a led circuit board, you should be fami. I would get some sort of powdered or granular metal (possibly lead) and mix it with small amounts of water. Every printed circuit board is manufactured to connect and support a particular circuit, and so all the tracks, pads, vias, etc., are calculated and designed in advance. Then i would fill the paste in an ink jet printer. Pcb design is a thorough and meticulous process that is considered both a science and an art.

Source: lowcostpcbassembly.wordpress.com

Source: lowcostpcbassembly.wordpress.com

When making a led circuit board, you should be fami. Printed circuit boards are typically made out of. The first step of the pcb manufacturing process is to make the substrate. The printed circuit board manufacturing process. When making a led circuit board, you should be fami.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title printed circuit boards are typically made out of by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.