Solid state welding process

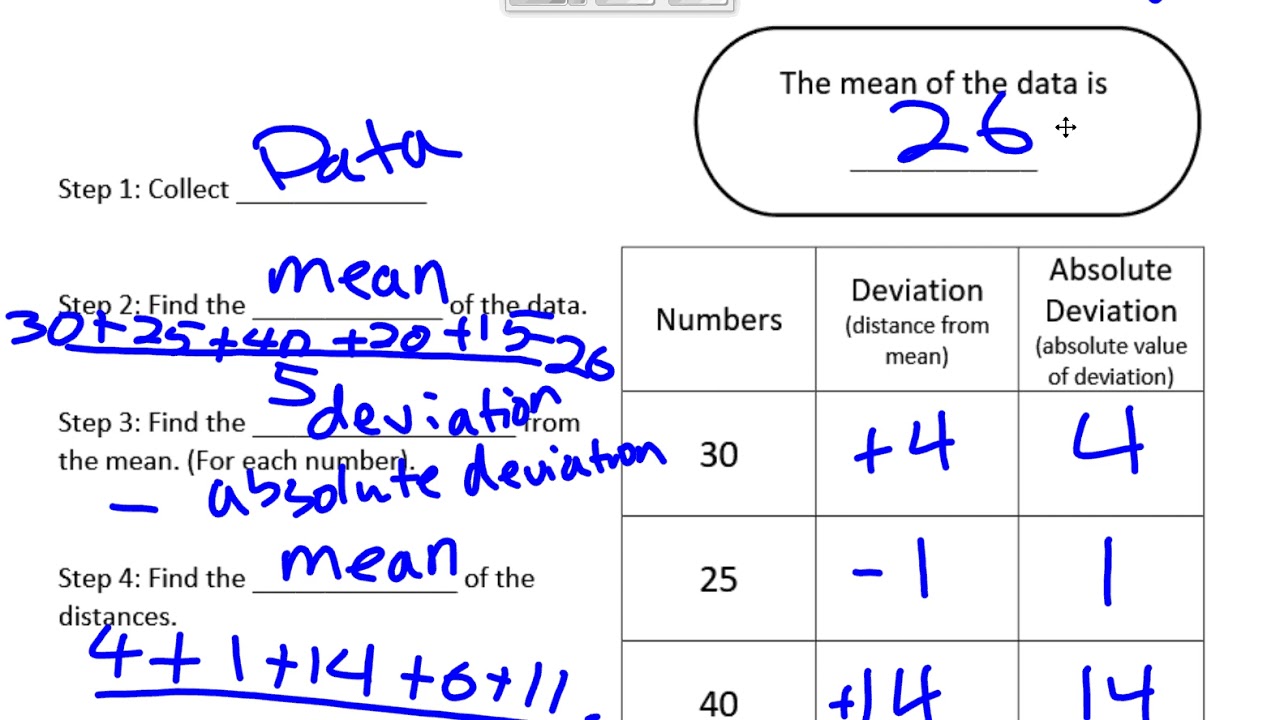

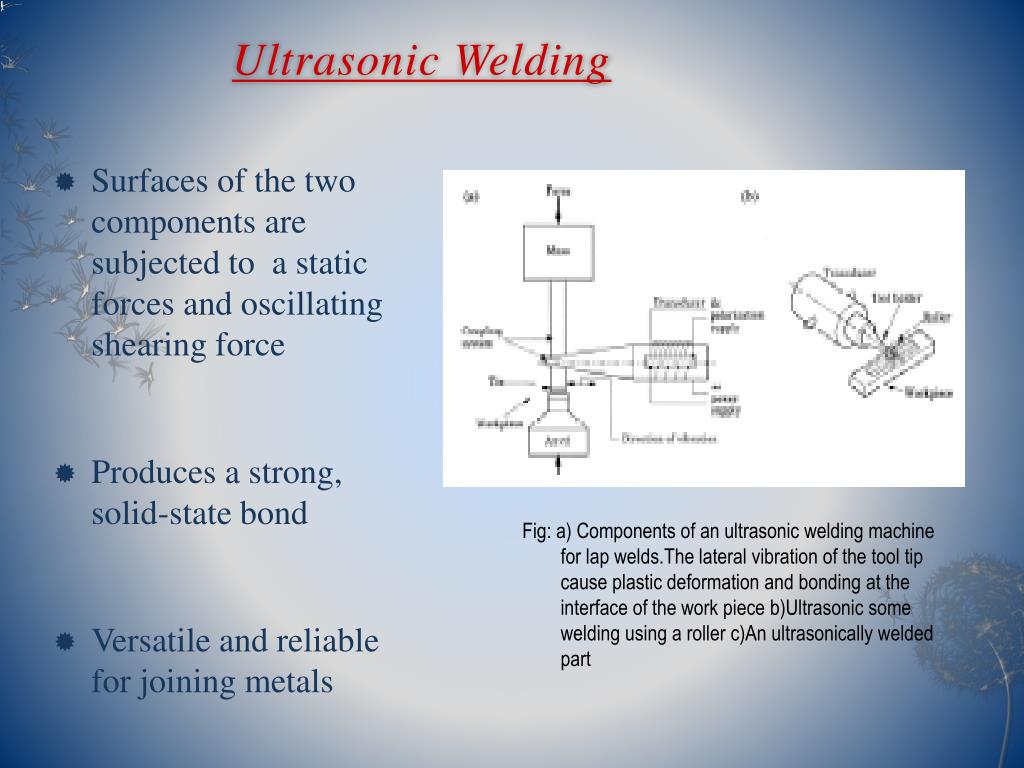

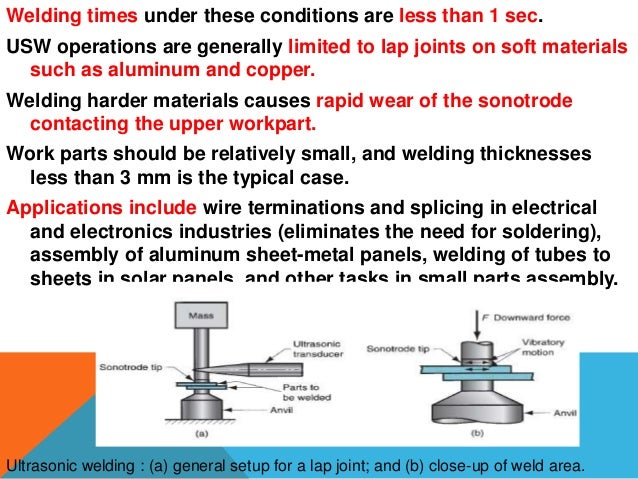

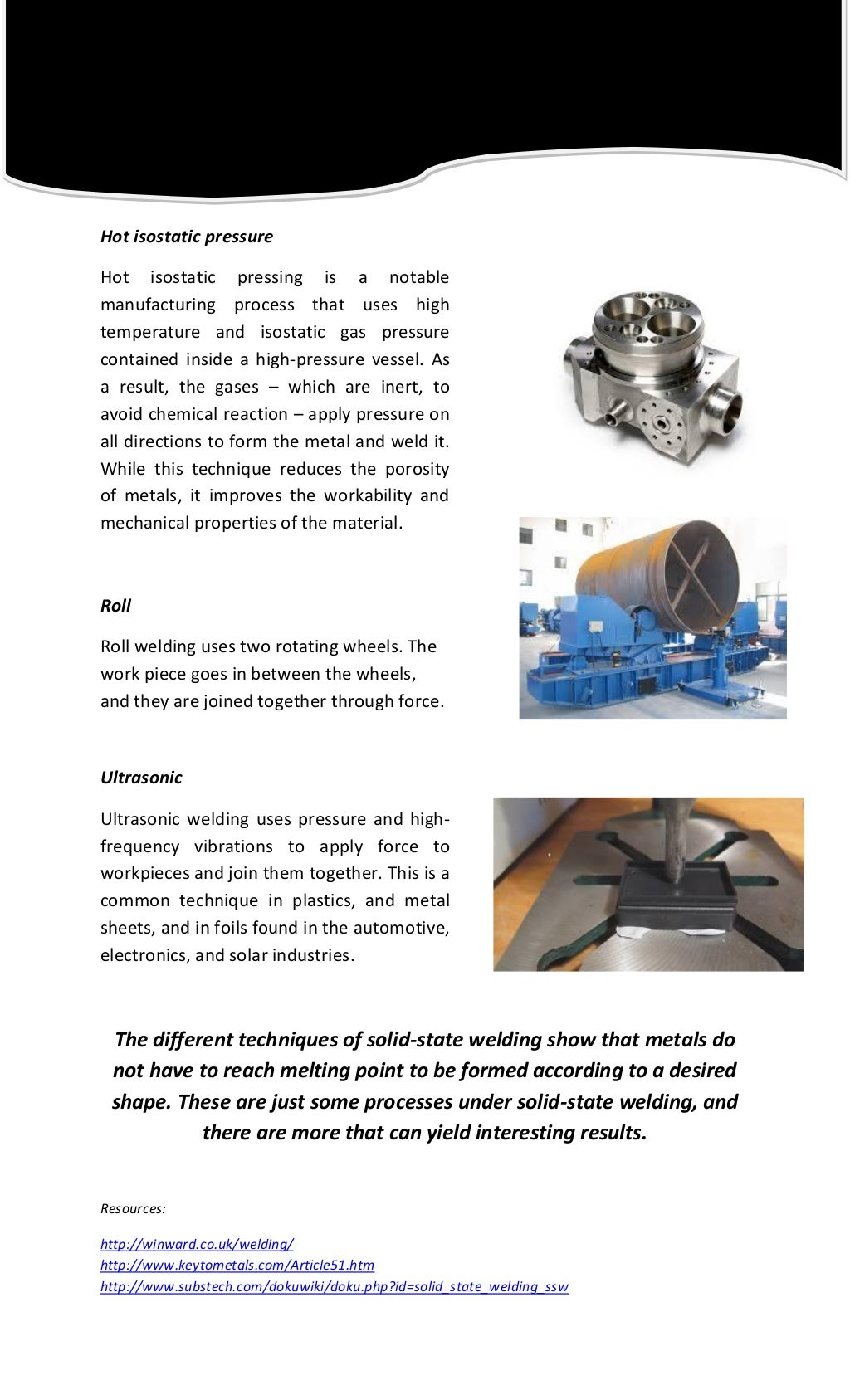

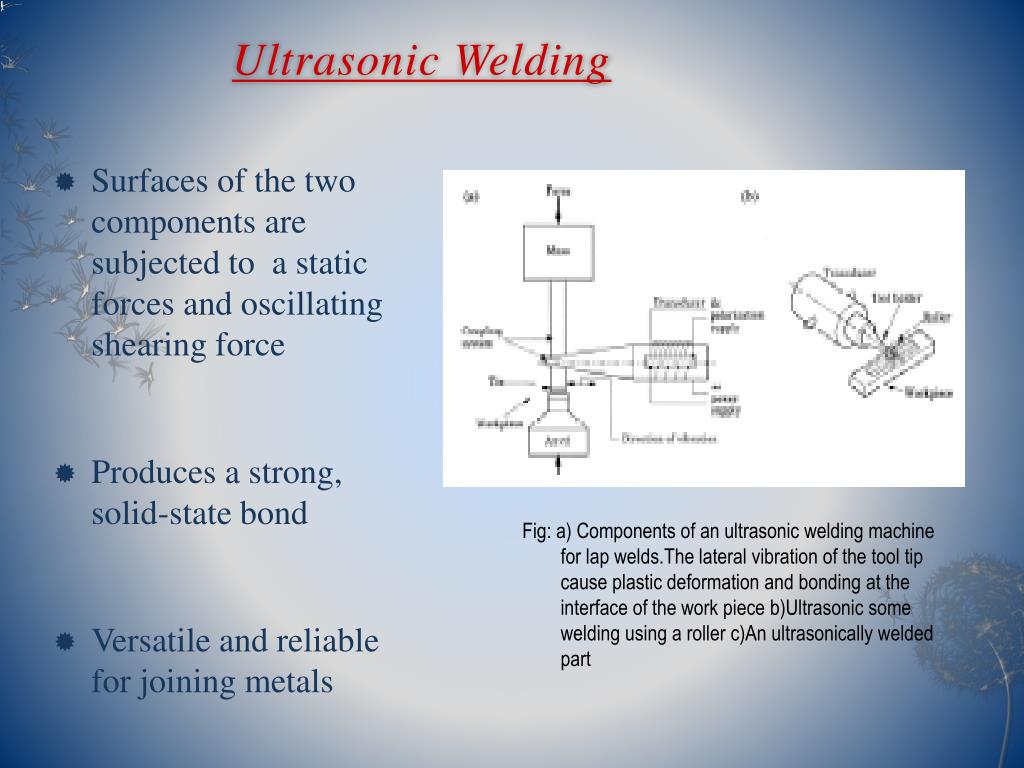

Solid State Welding Process. Solid‐state welding theory emphasizes that the driving force for two pieces of metal to spontaneously weld to each other exists if the barriers to welding can be eliminated. Prior to forge welding, the parts are scarfed in order to prevent entrapment of. A) components of an ultrasonic welding machine for lap welds.the lateral vibration of the tool tip cause plastic deformation and bonding at the interface of the work piece b)ultrasonic some welding using a roller c)an ultrasonically welded versatile and reliable part for joining metals friction welding. In all of these welding processes, time, temperature and pressure individually or in combination produce coalescence of the base metal without significant melting.

PPT SolidState Welding Process PowerPoint Presentation, free From slideserve.com

PPT SolidState Welding Process PowerPoint Presentation, free From slideserve.com

A) components of an ultrasonic welding machine for lap welds.the lateral vibration of the tool tip cause plastic deformation and bonding at the interface of the work piece b)ultrasonic some welding using a roller c)an ultrasonically welded versatile and reliable part for joining metals friction welding. In addition to melting the base metal, a filler material is typically added to. Much of that trust, however, comes from our ability to help throughout the development of a new production process, from tailoring technology to developing/executing. In diffusion bonding or diffusion welding a weld is achieved by the application of pressure, of the order of 5 to 75 n/mm 2, while the pieces are held at a high temperature, normally about 70% of the melting point in degrees absolute i.e. Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion.welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). Solid‐state welding theory emphasizes that the driving force for two pieces of metal to spontaneously weld to each other exists if the barriers to welding can be eliminated.

A) components of an ultrasonic welding machine for lap welds.the lateral vibration of the tool tip cause plastic deformation and bonding at the interface of the work piece b)ultrasonic some welding using a roller c)an ultrasonically welded versatile and reliable part for joining metals friction welding.

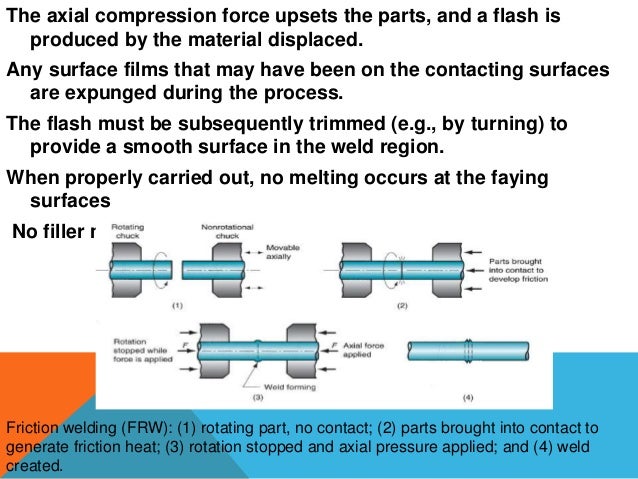

Friction welding (frw) explosive welding (exw) diffusion welding (dfw) ultrasonic welding (usw) forge welding (fow) forge welding is a solid state welding process, in which low carbon steel parts are heated to about 1800°f (1000°c) and then forged (hammered). Solid state welding solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material. The welding process in which two workpieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the base materials is known as solid state welding. Spot welding figure 31.6 (a) sequence of events in resistance spot welding. The materials being joined without the addition of the filler material. One of the solid state welding processes, called friction welding, is shown in figure 3.1.

Solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material. The materials being joined without the addition of the filler material. Spot welding figure 31.6 (a) sequence of events in resistance spot welding. Much of that trust, however, comes from our ability to help throughout the development of a new production process, from tailoring technology to developing/executing. Solid‐state welding theory emphasizes that the driving force for two pieces of metal to spontaneously weld to each other exists if the barriers to welding can be eliminated.

Source: pinterest.com

Source: pinterest.com

Much of that trust, however, comes from our ability to help throughout the development of a new production process, from tailoring technology to developing/executing. In addition to melting the base metal, a filler material is typically added to. The welding process in which two workpieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the base materials is known as solid state welding. Advantages of solid state welding weld (bonding) is free from microstructure defects. In all of these welding processes, time, temperature and pressure individually or in combination produce coalescence of the base metal without significant melting.

Source: pinterest.com

Source: pinterest.com

Each process in this group has its own unique way of creating the bond at the faying surfaces friction welding is a widely used commercial process, amenable to automated production methods. Prior to forge welding, the parts are scarfed in order to prevent entrapment of. Much of that trust, however, comes from our ability to help throughout the development of a new production process, from tailoring technology to developing/executing. Spot welding figure 31.6 (a) sequence of events in resistance spot welding. Advantages of solid state welding weld (bonding) is free from microstructure defects.

Source: es.slideshare.net

Source: es.slideshare.net

Solid state welding solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material. Prior to forge welding, the parts are scarfed in order to prevent entrapment of. A) components of an ultrasonic welding machine for lap welds.the lateral vibration of the tool tip cause plastic deformation and bonding at the interface of the work piece b)ultrasonic some welding using a roller c)an ultrasonically welded versatile and reliable part for joining metals friction welding. All solid‐state welding processes are based on this concept, and use some combination of heat, pressure, and time to overcome the barriers. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the fsw tool.

Source: slideshare.net

Source: slideshare.net

Much of that trust, however, comes from our ability to help throughout the development of a new production process, from tailoring technology to developing/executing. Advantages of solid state welding weld (bonding) is free from microstructure defects. In diffusion bonding or diffusion welding a weld is achieved by the application of pressure, of the order of 5 to 75 n/mm 2, while the pieces are held at a high temperature, normally about 70% of the melting point in degrees absolute i.e. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the fsw tool. The process is based on solid.

Source: slideshare.net

Source: slideshare.net

Solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material. Each process in this group has its own unique way of creating the bond at the faying surfaces friction welding is a widely used commercial process, amenable to automated production methods. The process is based on solid. Solid state welding solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the fsw tool.

Source: slideshare.net

Source: slideshare.net

Much of that trust, however, comes from our ability to help throughout the development of a new production process, from tailoring technology to developing/executing. Solid‐state welding theory emphasizes that the driving force for two pieces of metal to spontaneously weld to each other exists if the barriers to welding can be eliminated. Prior to forge welding, the parts are scarfed in order to prevent entrapment of. The materials being joined without the addition of the filler material. In all of these welding processes, time, temperature and pressure individually or in combination produce coalescence of the base metal without significant melting.

Source: ptc-innovation.se

Source: ptc-innovation.se

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion.welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). The heat for welding is generated by mechanically induced sliding motion between rubbing surfaces of workpieces in this process. Solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material. Advantages of solid state welding weld (bonding) is free from microstructure defects. Much of that trust, however, comes from our ability to help throughout the development of a new production process, from tailoring technology to developing/executing.

Source: pinterest.com

Source: pinterest.com

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion.welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). One of the solid state welding processes, called friction welding, is shown in figure 3.1. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the fsw tool. In addition to melting the base metal, a filler material is typically added to. The welding process in which two workpieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the base materials is known as solid state welding.

Source: slideshare.net

Source: slideshare.net

Each process in this group has its own unique way of creating the bond at the faying surfaces friction welding is a widely used commercial process, amenable to automated production methods. Advantages of solid state welding weld (bonding) is free from microstructure defects. One of the solid state welding processes, called friction welding, is shown in figure 3.1. Each process in this group has its own unique way of creating the bond at the faying surfaces friction welding is a widely used commercial process, amenable to automated production methods. Much of that trust, however, comes from our ability to help throughout the development of a new production process, from tailoring technology to developing/executing.

Source: slideserve.com

Source: slideserve.com

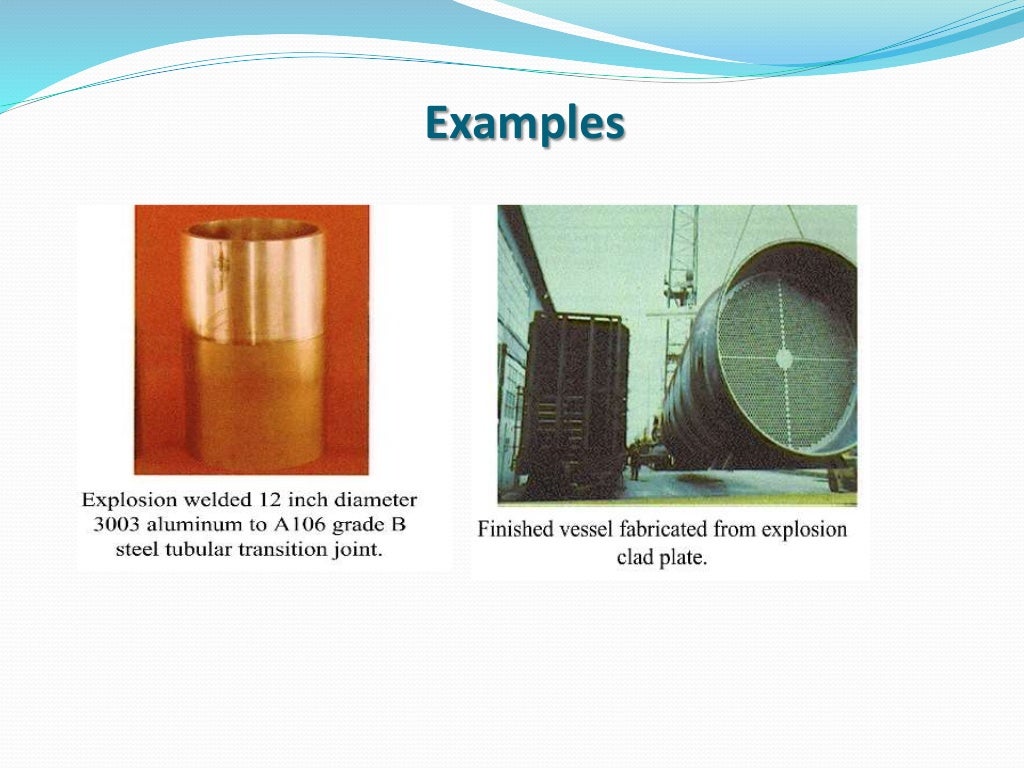

Prior to forge welding, the parts are scarfed in order to prevent entrapment of. In diffusion bonding or diffusion welding a weld is achieved by the application of pressure, of the order of 5 to 75 n/mm 2, while the pieces are held at a high temperature, normally about 70% of the melting point in degrees absolute i.e. Friction welding (frw) explosive welding (exw) diffusion welding (dfw) ultrasonic welding (usw) forge welding (fow) forge welding is a solid state welding process, in which low carbon steel parts are heated to about 1800°f (1000°c) and then forged (hammered). Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion.welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). Spot welding figure 31.6 (a) sequence of events in resistance spot welding.

Source: pinterest.com

Source: pinterest.com

Mechanical properties of the weld are similar to those of the parent metals. Spot welding figure 31.6 (a) sequence of events in resistance spot welding. In diffusion bonding or diffusion welding a weld is achieved by the application of pressure, of the order of 5 to 75 n/mm 2, while the pieces are held at a high temperature, normally about 70% of the melting point in degrees absolute i.e. Solid state welding solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material. Spot welding figure 31.6 (a) sequence of events in resistance spot welding.

Source: youtube.com

Source: youtube.com

Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the fsw tool. Solid state welding solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material. The heat for welding is generated by mechanically induced sliding motion between rubbing surfaces of workpieces in this process. In addition to melting the base metal, a filler material is typically added to. A) components of an ultrasonic welding machine for lap welds.the lateral vibration of the tool tip cause plastic deformation and bonding at the interface of the work piece b)ultrasonic some welding using a roller c)an ultrasonically welded versatile and reliable part for joining metals friction welding.

Source: slideshare.net

Source: slideshare.net

In addition to melting the base metal, a filler material is typically added to. The materials being joined without the addition of the filler material. Solid state welding is the oldest welding process and some of them are the newest. Spot welding figure 31.6 (a) sequence of events in resistance spot welding. Prior to forge welding, the parts are scarfed in order to prevent entrapment of.

Solid state welding is the oldest welding process and some of them are the newest. Solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material. Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion.welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). The welding process in which two workpieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the base materials is known as solid state welding. In all of these welding processes, time, temperature and pressure individually or in combination produce coalescence of the base metal without significant melting.

![Solid State Welding Processes [PPT Powerpoint] Solid State Welding Processes [PPT Powerpoint]](https://reader015.vdocuments.mx/reader015/slide/20170902/552171d64a795963718b4ba9/document-14.png?t=1631539765) Source: vdocuments.mx

Source: vdocuments.mx

Solid‐state welding theory emphasizes that the driving force for two pieces of metal to spontaneously weld to each other exists if the barriers to welding can be eliminated. In addition to melting the base metal, a filler material is typically added to. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the fsw tool. Solid state welding is the oldest welding process and some of them are the newest. Mechanical properties of the weld are similar to those of the parent metals.

Source: mech4study.com

Source: mech4study.com

Spot welding figure 31.6 (a) sequence of events in resistance spot welding. Solid state welding solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material. Friction welding (frw) explosive welding (exw) diffusion welding (dfw) ultrasonic welding (usw) forge welding (fow) forge welding is a solid state welding process, in which low carbon steel parts are heated to about 1800°f (1000°c) and then forged (hammered). Much of that trust, however, comes from our ability to help throughout the development of a new production process, from tailoring technology to developing/executing. The process is based on solid.

Source: slideserve.com

Source: slideserve.com

Prior to forge welding, the parts are scarfed in order to prevent entrapment of. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the fsw tool. Mechanical properties of the weld are similar to those of the parent metals. In addition to melting the base metal, a filler material is typically added to. Solid state welding solid state welding is a welding process, in which two work pieces are joined under a pressure providing an intimate contact between them and at a temperature essentially below the melting point of the parent material.

If you find this site serviceableness, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title solid state welding process by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.