Types of rivets their applications

Types Of Rivets Their Applications. Rivets come in a surprising array of different types. Solid rivet functions as center pin of hinge assembly. Rivets are made up of two parts: Across the various types of rivets that are used within aviation, there are solid, blind, structural, split, flush, and friction rivets.

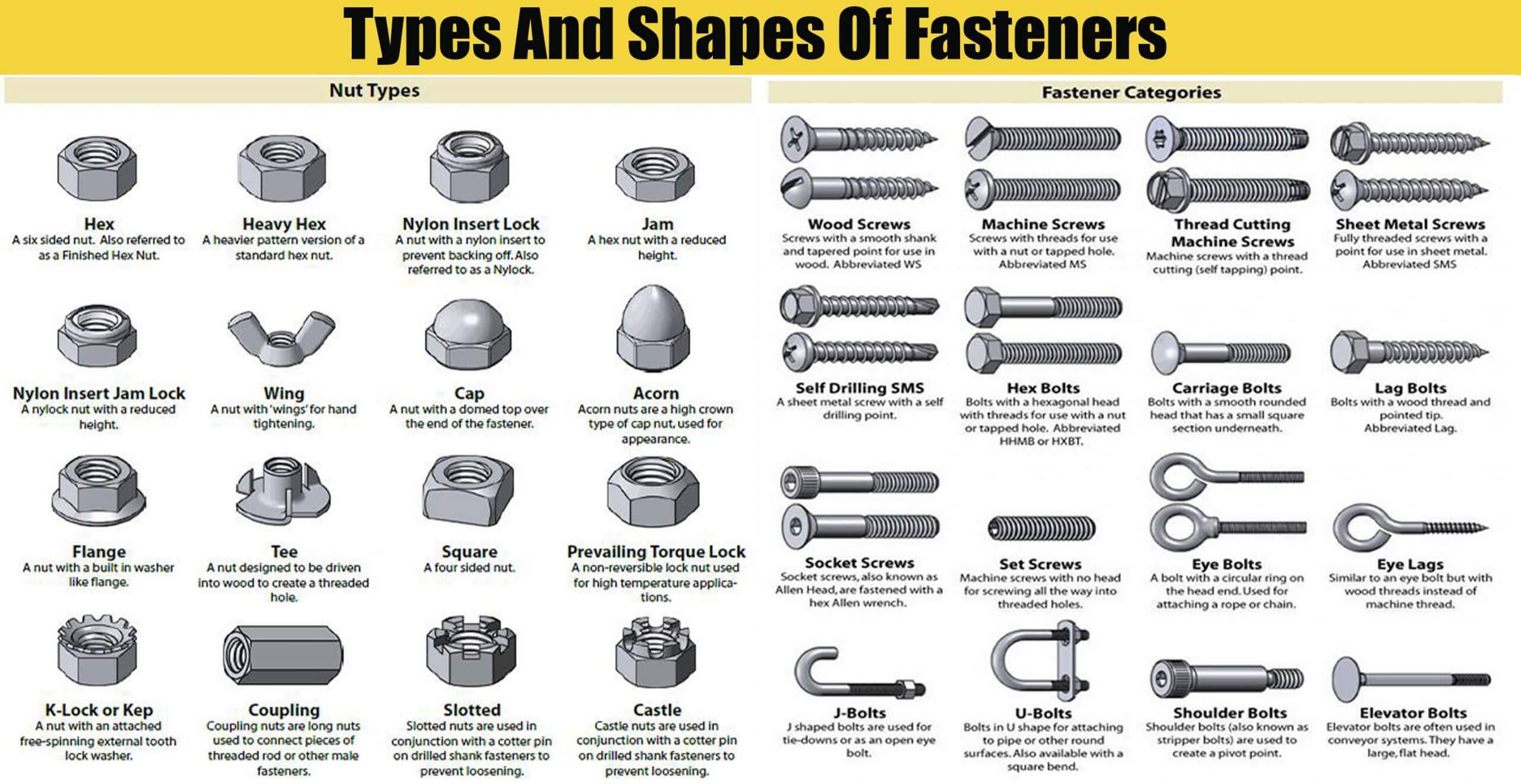

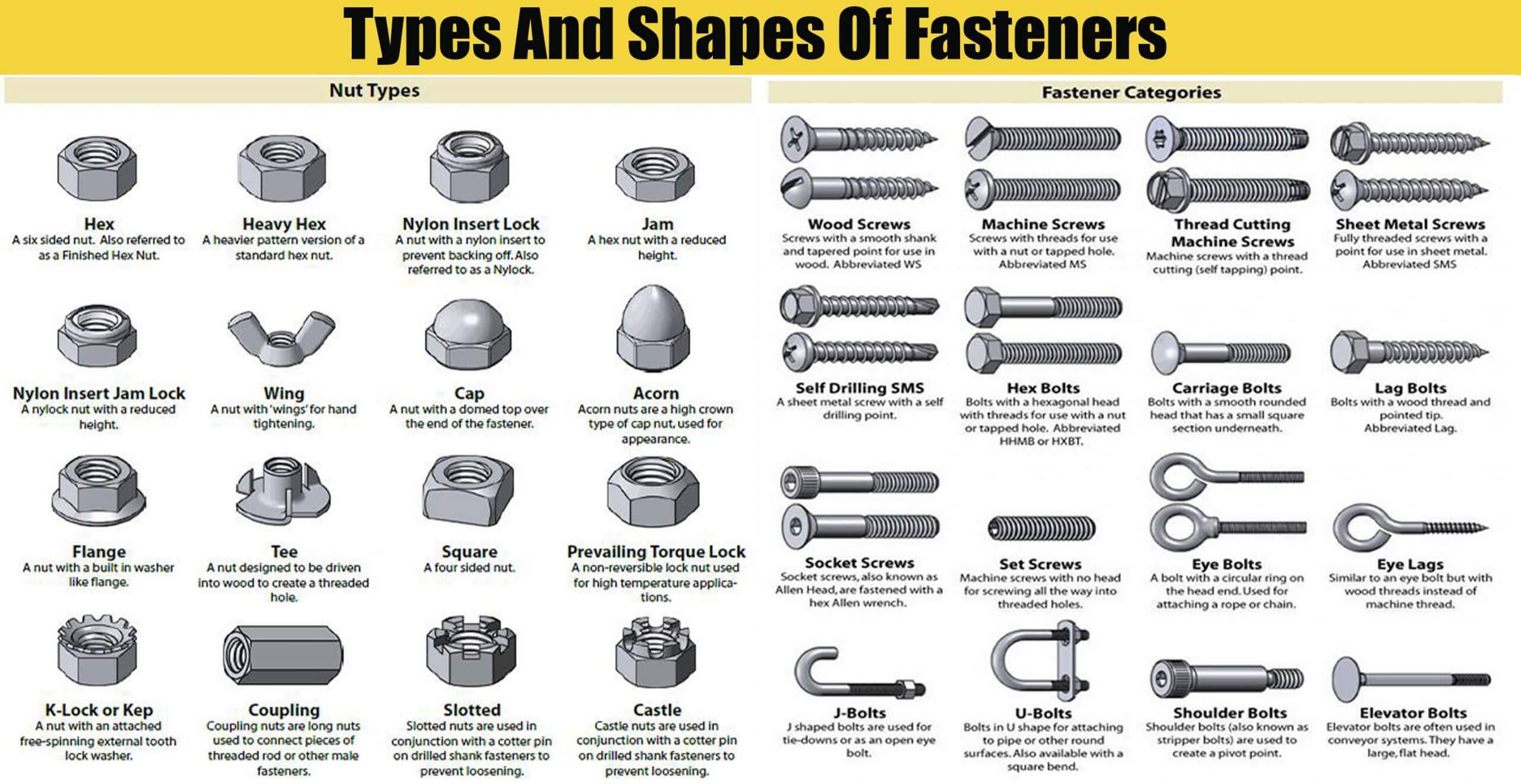

Types And Shapes Of Fasteners, Nuts, Screw Head, And washers From engineeringdiscoveries.com

Types And Shapes Of Fasteners, Nuts, Screw Head, And washers From engineeringdiscoveries.com

Our rivets are available in various dimensions, diameters, finishes and materials. They are also the most commonly used ones. The end opposite to the head is called the tail.on installation, the rivet is placed in a punched or drilled hole, and the tail is upset, or bucked (i.e., deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in. Rivets come in a surprising array of different types. Just in simple words the parts used to join together with the help of the rivet is known as the riveting process. Sold rivets are made up of a solid shaft with a head at one end.

The different types of rivets are as follows:

While not all rivet guns were made equal, it is easy to identify the type of rivet gun needed for an application. These tools are called rivets. Rivets come in various kinds of shapes and sizes to meet the various kinds of requirements. The different types of rivets are as follows: Aluminum provides strong corrosion resistance and is ideal for many applications. Some types of tubular rivets include compression, full tubular, and semitubular.

![12 Different Types of Fasteners Their Uses & Examples [PDF] 12 Different Types of Fasteners Their Uses & Examples [PDF]](https://www.theengineerspost.com/wp-content/uploads/2021/08/Types-of-bolts-1-min-768x644.jpg) Source: theengineerspost.com

Source: theengineerspost.com

Just in simple words the parts used to join together with the help of the rivet is known as the riveting process. 6 common types of rivets used in the aircraft industry. Rivets come in a surprising array of different types. The kind of rivet to be used depends on the application it is required in. Solid rivet functions as center pin of hinge assembly.

Source: pinterest.com

Source: pinterest.com

Ideal for projects where access to joints is limited to one side only. Blind rivets get their name from facts that they can be set completely aside. Ideal for projects where access to joints is limited to one side only. The rivet body, shell, or hat, and the stem or mandrel. Our fastener standards are all subject to complete inspection and are fully traceable with certification available.

Source: provenproductivity.com

Source: provenproductivity.com

A rivet is a type of fastener that’s used in the permanent assembly of a product or workpiece. More economical than cast pulley, more durable than spot welds. The rivets are kind of the adjacent surfaces between the two parts to be joined. The design of the hole helps to reduce the force required when rolling the tubular outward. Starting with the multilock rivet, it is a structural rivet that is distinguished by a grooved shoulder on the shank, which provides good hole filling in all applications.;

![Types of Rivets and Their Uses [with Pictures] Engineering Learner Types of Rivets and Their Uses [with Pictures] Engineering Learner](https://engineeringlearn.com/wp-content/uploads/2021/03/Types-of-Rivets-1024x539.jpg) Source: engineeringlearner.com

Source: engineeringlearner.com

Rivets come in a surprising array of different types. A straight metal piece will be inserted via the hole or cavity provided for. Common applications of the tubular rivet are ladders, ducting systems, lighting, binders, electronics, mechanical product, etc. Door hinge and pulley (solid rivet) the door hinge and pulley applications below both use solid rivets for strength and durability. The readily available materials are varying from steel, stainless, to brass, aluminum, and also copper.

Source: pinterest.com

Source: pinterest.com

The common applications of tubular rivets are lighting, brakes, ladders, binders, hvac ductwork, mechanical items, and also electronic devices. The different types of rivets are. Some types of tubular rivets include compression, full tubular, and semitubular. Instructions are given for setting the four most common types: Blind rivets get their name from facts that they can be set completely aside.

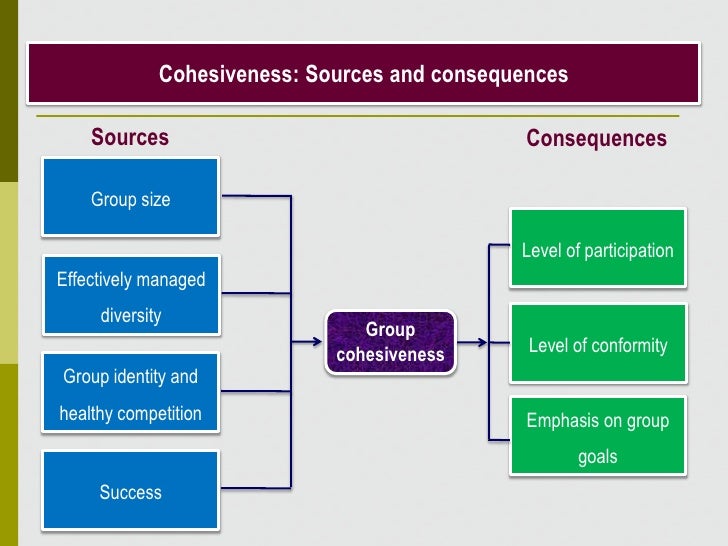

Source: engineeringdiscoveries.com

Source: engineeringdiscoveries.com

Types of rivets and its applications. Due to the demands placed on us by customers for more demanding sectors, bralo proposed designing new types of structural rivets: Solid rivets are one of the simplest and reliable types of rivets. The readily available materials are varying from steel, stainless, to brass, aluminum, and also copper. Across the various types of rivets that are used within aviation, there are solid, blind, structural, split, flush, and friction rivets.

![12 Different Types of Fasteners Their Uses & Examples [PDF] 12 Different Types of Fasteners Their Uses & Examples [PDF]](https://www.theengineerspost.com/wp-content/uploads/2021/08/Types-of-screws-1-min-768x644.jpg) Source: theengineerspost.com

Source: theengineerspost.com

Just in simple words the parts used to join together with the help of the rivet is known as the riveting process. This method increases the strength of the joint. Our rivets are available in various dimensions, diameters, finishes and materials. Starting with the multilock rivet, it is a structural rivet that is distinguished by a grooved shoulder on the shank, which provides good hole filling in all applications.; The rivets are kind of the adjacent surfaces between the two parts to be joined.

Source: goebelfasteners.com

Source: goebelfasteners.com

Solid rivets are one of the simplest and reliable types of rivets. The different types of rivets are. In the manufacturing industry, specific tools are used to attach different components together to make a fully functional product. Instructions are given for setting the four most common types: A rivet is a device that connects two metal parts together by a single mechanical force.

Source: helicoil.in

Source: helicoil.in

Solid rivets are the most common rivet type and one of the oldest fasteners, having existed for thousands of years across civilizations such as ancient. They are also the most commonly used ones. Starting with the multilock rivet, it is a structural rivet that is distinguished by a grooved shoulder on the shank, which provides good hole filling in all applications.; The design of the hole helps to reduce the force required when rolling the tubular outward. Sold rivets are made up of a solid shaft with a head at one end.

Source: goebelfasteners.com

Source: goebelfasteners.com

Common applications of the tubular rivet are ladders, ducting systems, lighting, binders, electronics, mechanical product, etc. Due to the demands placed on us by customers for more demanding sectors, bralo proposed designing new types of structural rivets: The different types of rivets are as follows: Sold rivets are made up of a solid shaft with a head at one end. The rivet body, shell, or hat, and the stem or mandrel.

![12 Different Types of Fasteners Their Uses & Examples [PDF] 12 Different Types of Fasteners Their Uses & Examples [PDF]](https://www.theengineerspost.com/wp-content/uploads/2021/08/Types-of-nuts-1-min-768x644.jpg) Source: theengineerspost.com

Source: theengineerspost.com

Due to the demands placed on us by customers for more demanding sectors, bralo proposed designing new types of structural rivets: 6 common types of rivets used in the aircraft industry. The kind of rivet to be used depends on the application it is required in. Starting with the multilock rivet, it is a structural rivet that is distinguished by a grooved shoulder on the shank, which provides good hole filling in all applications.; The readily available materials are varying from steel, stainless, to brass, aluminum, and also copper.

![12 Different Types of Fasteners Their Uses & Examples [PDF] 12 Different Types of Fasteners Their Uses & Examples [PDF]](https://www.theengineerspost.com/wp-content/uploads/2021/08/types-of-fasteners-min.jpg) Source: theengineerspost.com

Source: theengineerspost.com

Even today, rivets are still the preferred option for applications that demand permanent assembly. Aluminum provides strong corrosion resistance and is ideal for many applications. In the manufacturing industry, specific tools are used to attach different components together to make a fully functional product. Rivets are mechanical fasteners that come with a head and tail on opposite ends. In addition, it achieves greater resistance to vibrations even in those.

Source: uniriv.com

Source: uniriv.com

The different types of rivets are. The readily available materials are varying from steel, stainless, to brass, aluminum, and also copper. The kind of rivet to be used depends on the application it is required in. Types of rivets and its applications. Aluminum provides strong corrosion resistance and is ideal for many applications.

![12 Different Types of Fasteners Their Uses & Examples [PDF] 12 Different Types of Fasteners Their Uses & Examples [PDF]](https://www.theengineerspost.com/wp-content/uploads/2021/08/Types-of-Clevis-Pin-and-Cotter-Pin-min-768x644.jpg) Source: theengineerspost.com

Source: theengineerspost.com

Blind rivets, also called pop rivets, are a type of tubular rivets with a mandrel through their center. The rivet body, shell, or hat, and the stem or mandrel. Common applications of the tubular rivet are ladders, ducting systems, lighting, binders, electronics, mechanical product, etc. A rivet is a device that connects two metal parts together by a single mechanical force. 6 common types of rivets used in the aircraft industry.

Source: goebelfasteners.com

Source: goebelfasteners.com

This method increases the strength of the joint. They are also the most commonly used ones. The design of the hole helps to reduce the force required when rolling the tubular outward. Blind rivets, also known as pop rivets, are commonly used in applications where the rear (blind side) of the joint cannot be accessed. Our fastener standards are all subject to complete inspection and are fully traceable with certification available.

Source: jenniferbeesonblog.com

Source: jenniferbeesonblog.com

Solid rivets are the most common rivet type and one of the oldest fasteners, having existed for thousands of years across civilizations such as ancient. Sold rivets are made up of a solid shaft with a head at one end. Aluminum provides strong corrosion resistance and is ideal for many applications. Types of rivets for leather. Starting with the multilock rivet, it is a structural rivet that is distinguished by a grooved shoulder on the shank, which provides good hole filling in all applications.;

![12 Different Types of Fasteners Their Uses & Examples [PDF] 12 Different Types of Fasteners Their Uses & Examples [PDF]](https://www.theengineerspost.com/wp-content/uploads/2021/08/Types-of-Rivets-2-min.jpg) Source: theengineerspost.com

Source: theengineerspost.com

The readily available materials are varying from steel, stainless, to brass, aluminum, and also copper. A straight metal piece will be inserted via the hole or cavity provided for. The design of the hole helps to reduce the force required when rolling the tubular outward. The common applications of tubular rivets are lighting, brakes, ladders, binders, hvac ductwork, mechanical items, and also electronic devices. Aluminum provides strong corrosion resistance and is ideal for many applications.

![12 Different Types of Fasteners Their Uses & Examples [PDF] 12 Different Types of Fasteners Their Uses & Examples [PDF]](https://www.theengineerspost.com/wp-content/uploads/2021/08/Types-of-Rivets-1-min-768x644.jpg) Source: theengineerspost.com

Source: theengineerspost.com

Sold rivets are made up of a solid shaft with a head at one end. Blind rivets, also called pop rivets, are a type of tubular rivets with a mandrel through their center. The rivets are kind of the adjacent surfaces between the two parts to be joined. Types of rivets for leather. Blind rivets get their name from facts that they can be set completely aside.

If you find this site helpful, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title types of rivets their applications by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.