Drill press safety rules

Drill Press Safety Rules. As soon as the hole is drilled, retrieve the bit. Drill press safety rules_3 revision date: Also, you should see the functions in the safety test of the drill press. Safety rules & basics for drill presses drill presses are designed for cutting holes into metals, plastics, and wood.

Drill Press Safety From woodworkboss.com

Drill Press Safety From woodworkboss.com

If the parts of the dp are working smoothly or having any trouble. Remove the chuck key before starting the drill press. Ppe/safety rules wear appropriate safety classes use a clamp or drill vise to prevent object from spinning. These protect the face from any shards and parts that may fly off the surface you are working on and the drill. • before starting the drill press, ensure that the critical controls are within easy reach and safeguards are in place. • inform your supervisor of any safety concerns or damage to the drill press.

Gloves must not be worn.

Sturdy footwear must be worn at all times in work areas. Drill press safety • ensure all safety shields and guards are. To avoid accidents, the following. Make sure the drill bit or cutting tool is locked securely in the chuck. Use a clamp or drill vise to prevent work from spinning. The safety rules associating with drill press machines are several actually.

Source: quora.com

Safety rules & basics for drill presses drill presses are designed for cutting holes into metals, plastics, and wood. Introduction to drill press safety. If the parts of the dp are working smoothly or having any trouble. Use a clamp or drill vise to prevent work from spinning. The safety rules associating with drill press machines are several actually.

Source: polleytechnical.com

Source: polleytechnical.com

• review safety data sheets to identify hazardous work materials and cutting fluids. Also, you should see the functions in the safety test of the drill press. The drilling machine operator may or may not be a skilled worker. The point of operation on the drill press cannot be completely guarded and therefore can cause injury when the users’ hands come in contact with the drill bits. Lubricate drill bit when drilling metal reduce pressure on the drill when drill breaks through the workpiece, to prevent drill from pulling into the workpiece and breaking.

Source: drillly.com

Source: drillly.com

The workspace should be as safe and tidy as possible. Understand the parts of the drill press that you might be using and/or maintaining for as long as you plan to have it. Be sure to always follow good safety practices in the shop as described in general robotics safety rules. • inform your supervisor of any safety concerns or damage to the drill press. If you need to know more about manufacturing safety here is your shopping list.

Source: themostspruce.com

Source: themostspruce.com

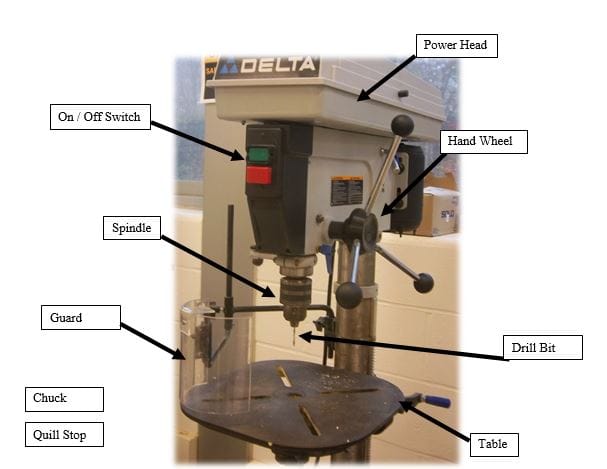

When making deep holes, clean out the hole frequently. Recall the bit out every once in a while to have deeper holes or for dense materials for the removal of waste. For depth, use the lock nut on the side of the spindle. The drill cords should always be clear of the cutting area. The most notable parts of a drill press include the quill, the drill chuck, the belt guard, the hand feeding level, the table and the base.

Source: manualsdir.com

Source: manualsdir.com

Use a clamp or drill vise to prevent work from spinning. Get proper safety glasses that you’ll be wearing all time and also pay attention to your clothes, make sure those are appropriate for this process. Know where the power button on your drill press is. See the product demonstration video and specifications for more. • don’t wear loose clothing or gloves, keep long hair tied back.

Source: quora.com

Make sure the drill bit or cutting tool is locked securely in the chuck. It has a motor driven head that has a chuck that accepts bits or cutters. Safety glasses must be worn at all times in work areas. Lubricate drill bit when drilling metal reduce pressure on the drill when drill breaks through the workpiece, to prevent drill from pulling into the workpiece and breaking. Get proper safety glasses that you’ll be wearing all time and also pay attention to your clothes, make sure those are appropriate for this process.

Source: safehazard.blogspot.com

Source: safehazard.blogspot.com

Safety rules • safety glasses are required. When making deep holes, clean out the hole frequently. Keep floor around the drill press free of oil and grease The operator also must change speeds and feeds when required. To avoid accidents, the following.

Source: slideshare.net

Source: slideshare.net

Keep floor around the drill press free of oil and grease Know where the power button on your drill press is. Lubricate drill bit when drilling metal reduce pressure on the drill when drill breaks through the workpiece, to prevent drill from pulling into the workpiece and breaking. It is operated by pulling a rotary lever which lowers the drill bit into the material. Long and loose hair must be contained.

Source: pinterest.com

Source: pinterest.com

The drill cords should always be clear of the cutting area. Drill press safety • ensure all safety shields and guards are. Gloves must not be worn. Introduction to drill press safety. Although a very commonly used piece of equipment, the rotating drill bit presents a safety risk if not used properly.

Source: pillardrillmachine.weebly.com

Source: pillardrillmachine.weebly.com

The workspace should be as safe and tidy as possible. For depth, use the lock nut on the side of the spindle. Safety rules & basics for drill presses drill presses are designed for cutting holes into metals, plastics, and wood. Take your time to go through each protocol and understanding those completely. See the product demonstration video and specifications for more.

Source: vimeopro.com

The workspace should be as safe and tidy as possible. The most notable parts of a drill press include the quill, the drill chuck, the belt guard, the hand feeding level, the table and the base. • tag defective equipment and remove it from service. The safety rules associating with drill press machines are several actually. Keep floor around the drill press free of oil and grease

• don’t wear loose clothing or gloves, keep long hair tied back. Also, you should see the functions in the safety test of the drill press. When making deep holes, clean out the hole frequently. These machines have variable speeds and some have multiple spindles for gang drilling. Lubricate drill bit when drilling metal reduce pressure on the drill when drill breaks through the workpiece, to prevent drill from pulling into the workpiece and breaking.

Source: youtube.com

Source: youtube.com

Introduction to drill press safety. Persons must read lab safety manual, machine manual, and be trained by wrl manager. Drill press safety and operation notice rules and guidelines listed on this page are only reminders. Know where the power button on your drill press is. Remove the chuck key before starting the drill press.

Source: themostspruce.com

Source: themostspruce.com

Drill press safety • ensure all safety shields and guards are. These items will get caught in bit or. When making deep holes, clean out the hole frequently. Safety rules • safety glasses are required. Use a clamp or drill vise to prevent work from spinning.

Source: quora.com

What are the safety rules for a drill press? Refer to the manufacturer’s operating manual for all operating procedures. These machines have variable speeds and some have multiple spindles for gang drilling. Safety rules & basics for drill presses drill presses are designed for cutting holes into metals, plastics, and wood. Also, you should see the functions in the safety test of the drill press.

Source: clarosa.rsd17.org

Source: clarosa.rsd17.org

Keep floor around the drill press free of oil and grease The workspace should be as safe and tidy as possible. • review safety data sheets to identify hazardous work materials and cutting fluids. The common drill press is used often by anybody in the shop and injuries can occur because of carelessness. Lubricate drill bit when drilling metal reduce pressure on the drill when drill breaks through the workpiece, to prevent drill from pulling into the workpiece and breaking.

Source: woodworkboss.com

Source: woodworkboss.com

The drill cords should always be clear of the cutting area. Use a clamp or drill vise to prevent work from spinning. The common drill press is used often by anybody in the shop and injuries can occur because of carelessness. Drill press safety and operation notice rules and guidelines listed on this page are only reminders. Before using a machine, you should check a few things, especially with electrically powered devices.

Source: pinterest.com

Source: pinterest.com

Practice use of your drill press. Here are a few of them to keep in mind. The drill cords should always be clear of the cutting area. There is different drill safety quiz available online. Before using a machine, you should check a few things, especially with electrically powered devices.

If you find this site helpful, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title drill press safety rules by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.