Injection pump parts and function

Injection Pump Parts And Function. Major technical advances arc not to be expected. The fuel injection pump is used in the individual pump system of a solid injection. These devices are typically used to manage nutrients and medications. Fuel injection system is the very important part of the compression ignition (ci) engine.

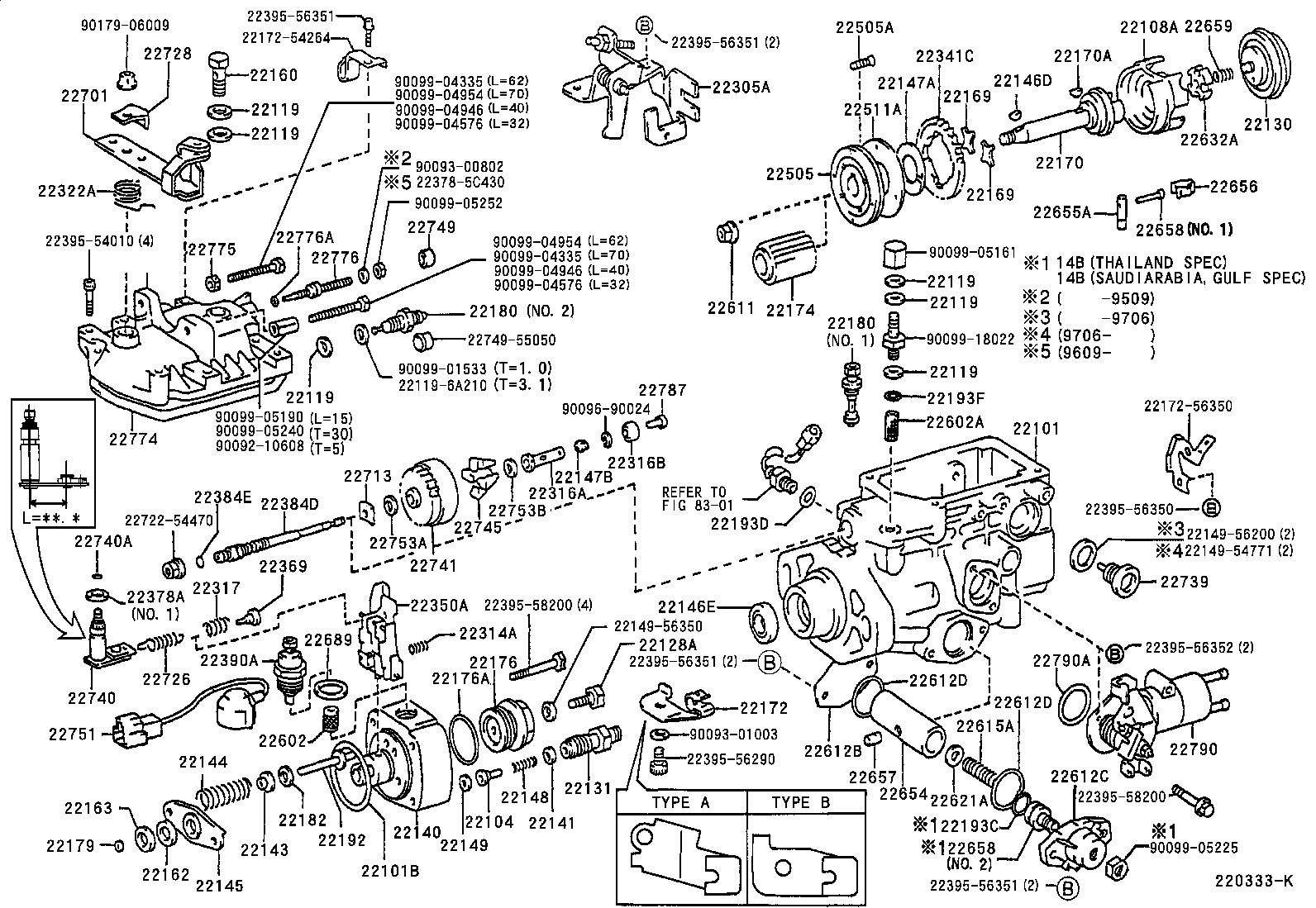

TOYOTA DYNAHU30LQRDT3 TOOLENGINEFUEL INJECTION PUMP ASSEMBLY From japan-parts.eu

TOYOTA DYNAHU30LQRDT3 TOOLENGINEFUEL INJECTION PUMP ASSEMBLY From japan-parts.eu

It can be said, in a 4 cylinder diesel engine there are 4 injectors and 4 plungers. Fuel injectors and fuel pumps are two crucial parts of cars today. Pump parts have been briefly described below: When the plunger is at the bottom of its stroke and supply as well as spill ports are uncovered. The performance of an engine viz. That is, each injector will be served by a plunger unit.

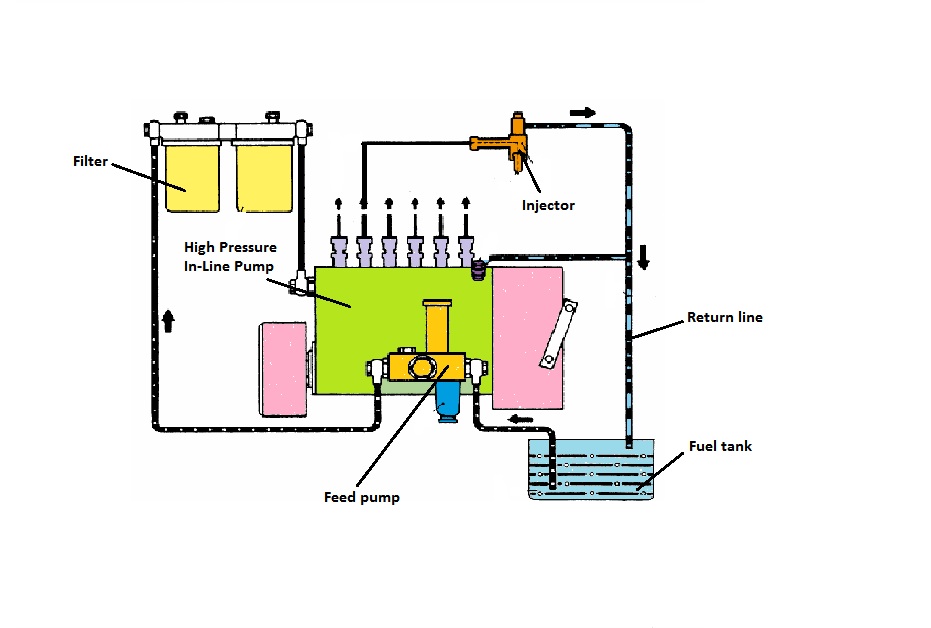

In an electronic fuel injection system, the fuel injection pump is used only for pressurizing the fuel line.

The oil from the fuel feed pump, after filtration, is forced into the barrel. That is, each injector will be served by a plunger unit. In pumps, the casing is basically used to seal it to prevent leakage and sometimes retain pressure. The injection pump parts and function available on the site are technologically advanced and equipped with all the latest features that you can rely upon. We are leading exporters of diesel fuel injection pump spares. Fuel injectors and fuel pumps are two crucial parts of cars today.

Source: reviewmotors.co

Source: reviewmotors.co

The crankshaft gear of the engine drives the camshaft to rotate to complete the fuel injection function. Usually, a peristaltic pump is present in this type of infusion pump. Fuel injectors and fuel pumps are two crucial parts of cars today. These stable and consistent performing. Injection provides better control of mixture enrichment than a carburetor.

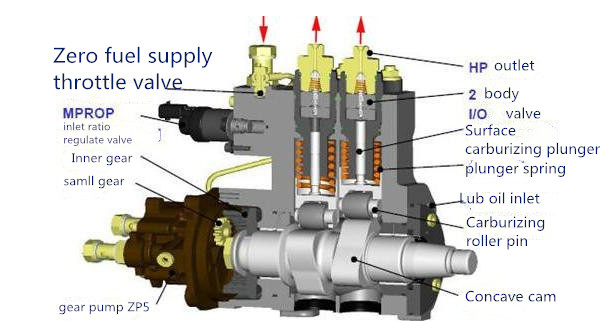

Source: dieseltester-cn.com

Source: dieseltester-cn.com

The crankshaft gear of the engine drives the camshaft to rotate to complete the fuel injection function. The performance of an engine viz. A screw pump is known for its low turbulence, ease of use with high viscous fluids, low vibration; Precise metering of fuel to each cylinder and increased airflow can result in more horsepower output. The injection pump parts and function available on the site are technologically advanced and equipped with all the latest features that you can rely upon.

Source: stratifiedauto.com

Source: stratifiedauto.com

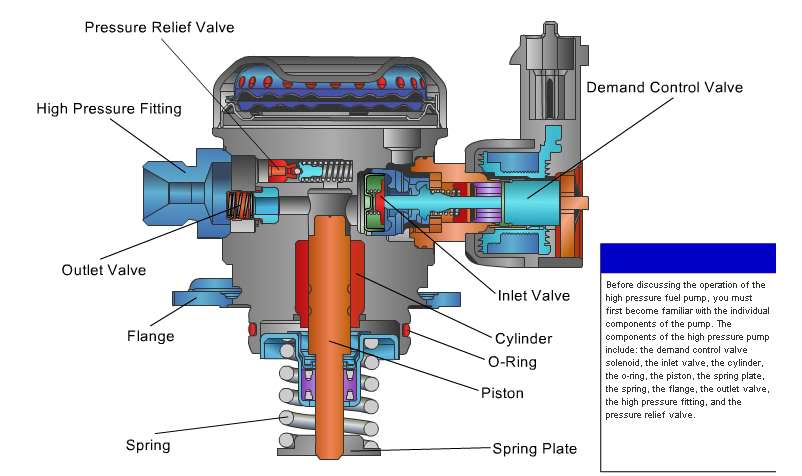

1] pumping fuel at high pressure: The crankshaft gear of the engine drives the camshaft to rotate to complete the fuel injection function. Inline injection pump is a high pressure pump on a diesel engine that is used to increase diesel fuel pressure up to 18,000 psi individually. The fuel injection pump or fuel injector is the “heart” of a diesel engine and the most critical component in the fuel supply system. These devices are typically used to manage nutrients and medications.

Source: howcarpartswork.blogspot.com

Source: howcarpartswork.blogspot.com

An infusion pump is a type of pump (syringe, peristaltic, and others) used to distribute fluids in a medical setting; Leading injection pump parts and function suppliers and wholesalers on the site offer these incredible pumps for the most competitive prices and deals that you can�t afford to miss out on. The crankshaft gear of the engine drives the camshaft to rotate to complete the fuel injection function. In an electronic fuel injection system, the fuel injection pump is used only for pressurizing the fuel line. Pump parts have been briefly described below:

Source: quora.com

Is largely dependent on the fuel injection system. It can be say, the number of plungers is the same as the number of injectors. 1] pumping fuel at high pressure: Fuel injection system is the very important part of the compression ignition (ci) engine. Usually, a peristaltic pump is present in this type of infusion pump.

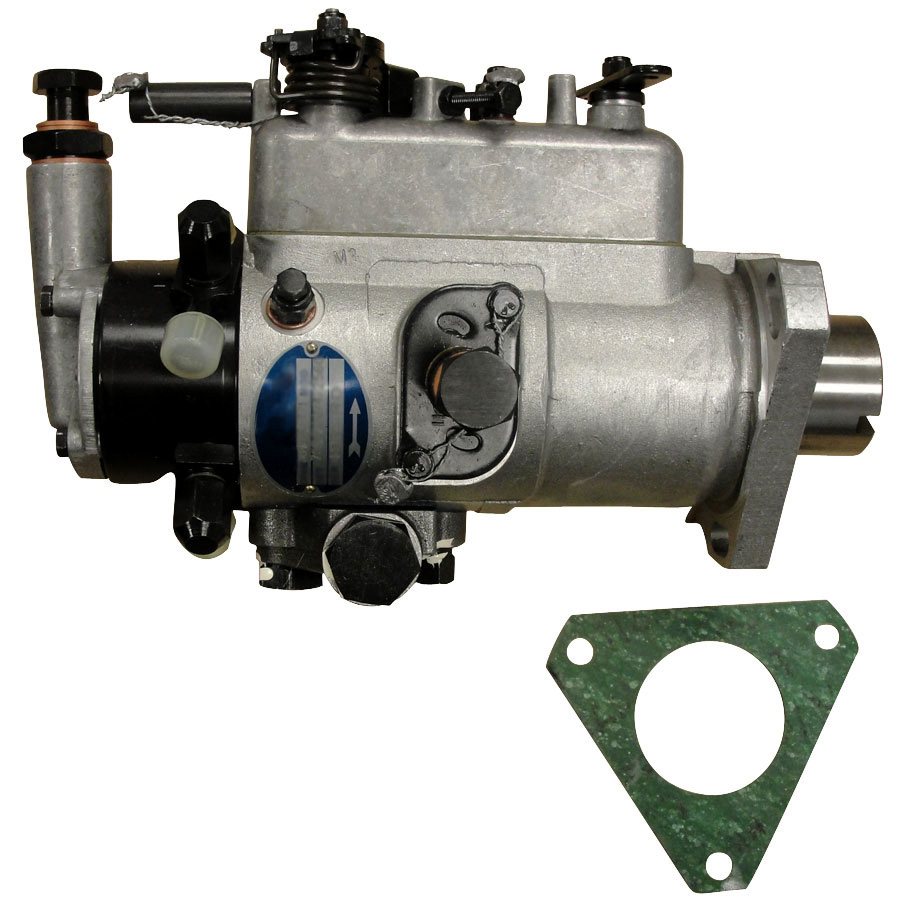

Source: fordntractor.com

Source: fordntractor.com

A screw pump is known for its low turbulence, ease of use with high viscous fluids, low vibration; Fuel transfer, high pressure fuel injection, lubrication and hydraulic power implication. A screw pump is known for its low turbulence, ease of use with high viscous fluids, low vibration; Large volume pumps are useful for infusing large volumes of fluid (about 500 ml). Machine function injection moulding machines are manufactured in.

Source: tractorjoe.com

Source: tractorjoe.com

The overall performance of diesel fuel injection pump depends on the injection system design. Is largely dependent on the fuel injection system. The process of injection moulding has today evolved to a high technical level. A screw pump is known for its low turbulence, ease of use with high viscous fluids, low vibration; 2] metering of the fuel:

Machine function injection moulding machines are manufactured in. 2] metering of the fuel: The fuel injection pump is an important part of the diesel engine. An infusion pump is a type of pump (syringe, peristaltic, and others) used to distribute fluids in a medical setting; Injection provides better control of mixture enrichment than a carburetor.

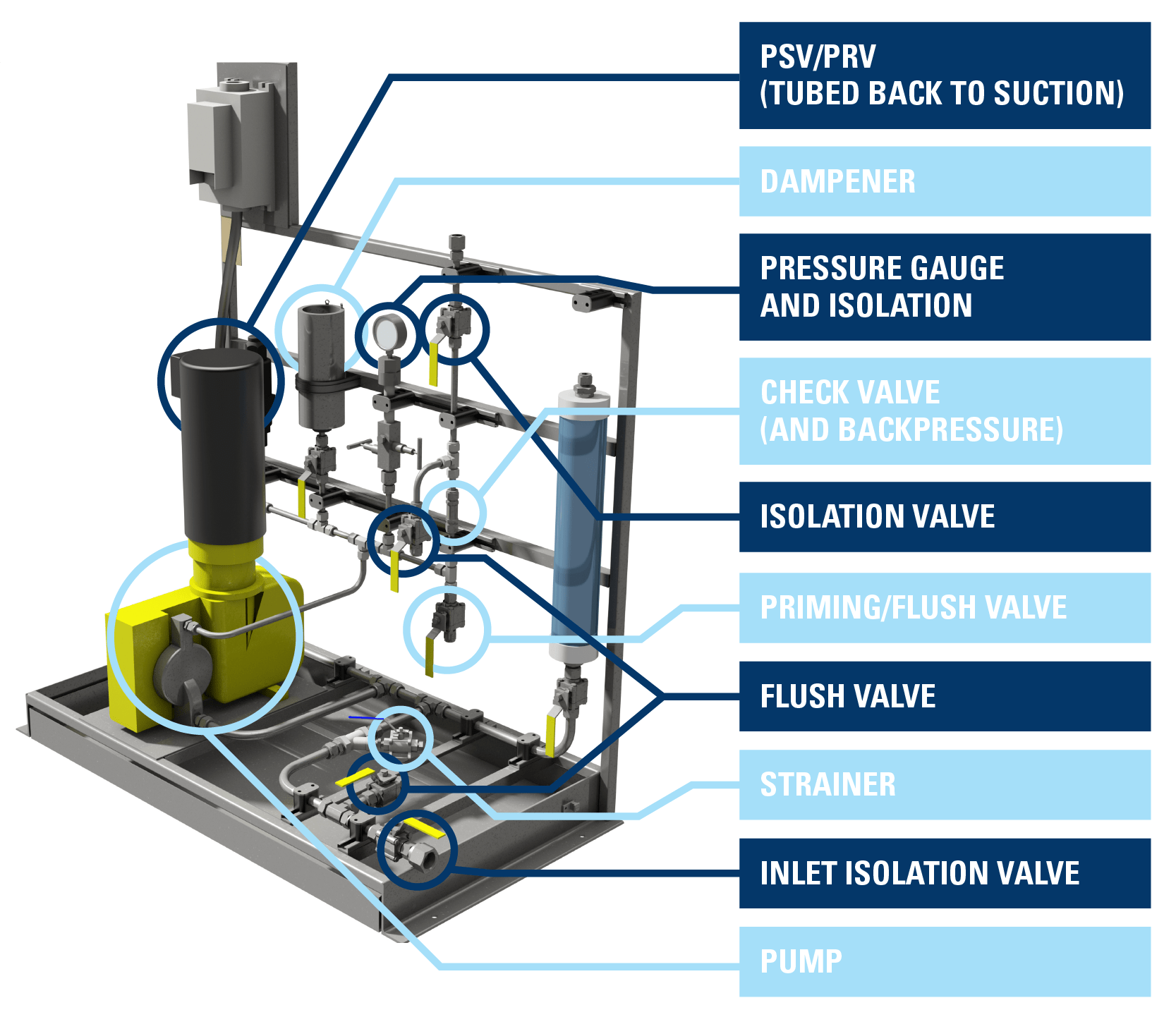

Source: wavecontrol.ca

Source: wavecontrol.ca

Is largely dependent on the fuel injection system. Major technical advances arc not to be expected. Fuel transfer, high pressure fuel injection, lubrication and hydraulic power implication. In pumps, the casing is basically used to seal it to prevent leakage and sometimes retain pressure. A screw pump is known for its low turbulence, ease of use with high viscous fluids, low vibration;

Source: japan-parts.eu

Source: japan-parts.eu

The fuel injection nozzle of the closed fuel injector is a pair of precision parts composed of a needle valve and a needle valve body, and its matching clearance is. Machine function injection moulding machines are manufactured in. Injection provides better control of mixture enrichment than a carburetor. It can be said, in a 4 cylinder diesel engine there are 4 injectors and 4 plungers. The fuel injection pump or fuel injector is the “heart” of a diesel engine and the most critical component in the fuel supply system.

Source: injectionpumps.co.uk

Source: injectionpumps.co.uk

So based on the type of pump used in the machine, they are mainly of two types. The fuel pump is usually equipped with a governor to ensure the low speed operation of the diesel engine and the limit. The passage is connected to the fuel atomizer. Fuel injectors and fuel pumps are two crucial parts of cars today. Leading injection pump parts and function suppliers and wholesalers on the site offer these incredible pumps for the most competitive prices and deals that you can�t afford to miss out on.

Source: lmfiqz.fezaiplik.com

Source: lmfiqz.fezaiplik.com

An infusion pump is a type of pump (syringe, peristaltic, and others) used to distribute fluids in a medical setting; The passage is connected to the fuel atomizer. Fuel injection system is the very important part of the compression ignition (ci) engine. Large volume pumps are useful for infusing large volumes of fluid (about 500 ml). The process of injection moulding has today evolved to a high technical level.

Source: japan-parts.eu

Source: japan-parts.eu

So based on the type of pump used in the machine, they are mainly of two types. This kind of fuel injector is mainly composed of fuel injector body, pressure regulating device and fuel injector. We are leading exporters of diesel fuel injection pump spares. The passage is connected to the fuel atomizer. 1] pumping fuel at high pressure:

Generally, the diesel fuel injection pump system performing encompasses. Both diesel components perform very different functions during the engine’s normal operating cycle despite having similar characteristics. Definition of inline injection pump. It can be a nutrient solution, saline solution, medications such as antibiotics, etc. The performance of an engine viz.

Source: fordntractor.com

Source: fordntractor.com

A casing can be explained as a shell, cover or a housing which protects and supports most of the components. Precise metering of fuel to each cylinder and increased airflow can result in more horsepower output. The injection pump parts and function available on the site are technologically advanced and equipped with all the latest features that you can rely upon. The passage is connected to the fuel atomizer. Large volume pumps are useful for infusing large volumes of fluid (about 500 ml).

Source: studentlesson.com

Source: studentlesson.com

Inline injection pump is a high pressure pump on a diesel engine that is used to increase diesel fuel pressure up to 18,000 psi individually. Fuel injection system is the very important part of the compression ignition (ci) engine. Usually, a peristaltic pump is present in this type of infusion pump. It can be divided into two systems. Injection provides better control of mixture enrichment than a carburetor.

It is the main function of the fuel injection pump. When the plunger is at the bottom of its stroke and supply as well as spill ports are uncovered. Injection provides better control of mixture enrichment than a carburetor. It is the main function of the fuel injection pump. It can be said, in a 4 cylinder diesel engine there are 4 injectors and 4 plungers.

Source: clubtechnical.com

Source: clubtechnical.com

Areas of interest to moulding machine designers and engineers include process control and quality assurance where inroads are still to be made as technology progresses. The crankshaft gear of the engine drives the camshaft to rotate to complete the fuel injection function. Generally, the diesel fuel injection pump system performing encompasses. The supply and the spill port are sealed at a certain stage when the plunger is pushed away. Usually, a peristaltic pump is present in this type of infusion pump.

If you find this site helpful, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title injection pump parts and function by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.